Bucket Elevator

Granular Material Processing Rate: 8~150 (T/H)

Powdery Material Processing Rate: 5~110 (T/H)

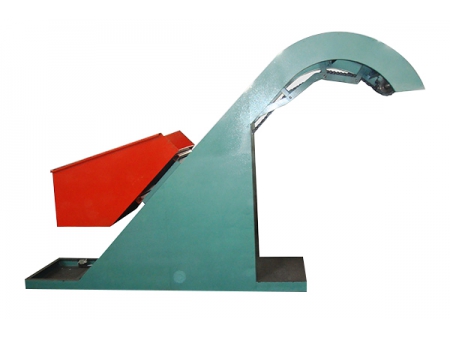

Head

Rubber covering technology is adopted for head pulley to increase friction coefficient and improve the driving efficiency of our bucket elevator; height of discharging section of head is increased, thus extending the materials discharging time. And it is fitted with outlet adjusting baffle plate and buffer chamber to effectively reduce the returning of materials.

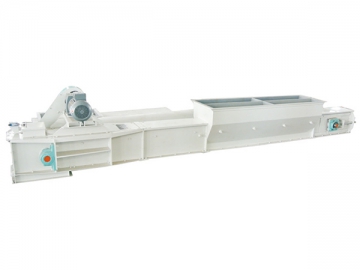

Housing

A bottom punch snap lock machine is used to create high-strength, leak-tight snap-lock seams that run the length of the bucket elevator housing. The balancing pipe is added to balance the pressure between two housings of machine body; Wide opening type access door facilitates the repair and replacing of bucket; Explosion-proof port is available and can effectively reduce pressure and release explosion.

Foot

New-type shaft end seal prevents dusts from leaking. Split structure of bearing housing guarantees the reliability of use of bucket elevator. Two sealing devices in the adjusting plate prevent the dust and materials from leaking out of the adjusting plate; the machine is fitted with anti-reversing device so as to avoid the blockage caused by power failure; It can be fitted with speed detecting and sideslip alarm device according to the requirement of user, ensuring safe and normal production.

| Model No.(TDTG) | ||||||||

| Granular Material Capacity(T/H) | 8 | 15-20 | 25-30 | 30-40 | 40-55 | 60-80 | 80-100 | 120-150 |

| Powdery Material Capacity(T/H) | 5 | 12-15 | 20-25 | 25-30 | 30-40 | 40-60 | 60-75 | 90-110 |