The OPLC optical composite cable are cables for long distance communications between stations, especially for applications needing high mechanical strength.

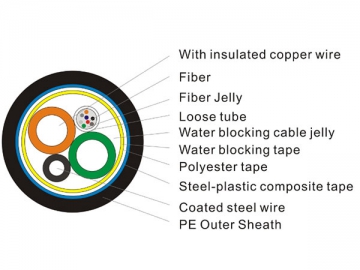

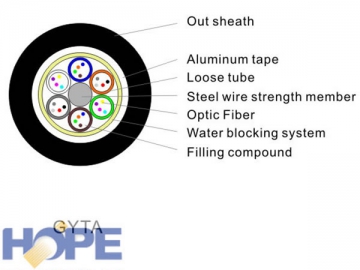

1. Cable Construction

Hybrid cable (Fiber and Power) cable structure

Features

1. Integrated cable and power line reduces secondary wiring and construction costs, especially over long distances.

2. Suitable for a variety of applications and businesses, such as internet access, phones, telecommunications, smart meters, and other services, in one cable.

3. Resistant to impact, lateral pressure, harsh environmental conditions, and fire.

4. Superior safety performance.

5. Compatible with long-term operating temperatures of power cable.

6. Quality materials, including plastics-coated steel tape, HDPE bounded outer sheath, and metallic central strength member (phosphate steel wire).

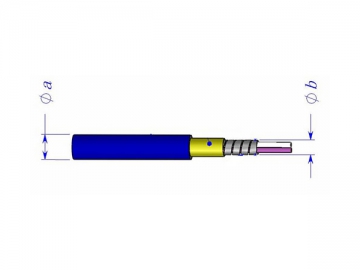

2. Cable Technical Data | Items | Structure |

| Power unit | 2×2.5m ㎡ |

| Conductor | Material | Annealed copper |

| Size | 1/3.5 mm |

| Inner sheath | Material | PVC Sheath |

| Color | Green, red |

| Outside diameter | 3.8±0.1mm |

| Fiber unit | 1B1.3 Fiber : 12cores |

| Dish cable | Fiber Type | | G652D |

| Fiber Number | | 12 |

| Color | Full Chromatography | |

| Armored | Waterproof tape | Material | Non Woven Fabric |

| Inner sheath | Material | Longitudinally corrugated steel composite tape |

| Outside diameter | 10.6±0.2mm |

| Outer sheath | Another inner sheath | Material | HDPE |

| Color | Black |

| Nominal thickness | 1.7mm |

| Outside diameter | 14±0.2mm |

| Cable mark | GDTS-12B 1.3 2*2.5m ㎡

|

3. Power configuration | Electric trait | Power line | Conductor DC resistance (20℃ ) | ≤7.41Ω/km |

| Operating voltage | 450/750V |

| Test voltage | 2500v |

| Insulation resistance | ≥0.009MΩ/km

|

4. Features of Optical Fiber | Geometrical properties | Mode field diameter | 9.3um±0.5um |

| Cladding diameter | 125um±1um |

| Core / cladding concentricity deviation | ≤0.6um |

| Cladding non-circularity | ≤1% |

| Diameter of the outer coating | 250um±15um |

| Coated cladding concentricity error | ≤12.5um |

| Attenuation characteristics | 1310nm OTDR attenuation | ≤0.40dB/km |

| 1550nm OTDR attenuation | ≤0.30dB/km |

| 1383nm OTDR attenuation | ≤0.40dB/km |

| 1625nm OTDR attenuation ≤0.35dB | ≤0.35dB/km |

| 1285nm - 1330nm within the range of maximum attenuation and compared 1310nm | ≤0.05dB/km |

| 1525nm - 1575nm within the range of maximum attenuation and compared 1550nm | ≤0.05dB/km |

| 1310nm, 1550nm attenuation discontinuities | ≤0.1dB |

| Dispersion characteristics | Zero dispersion wavelength | 1300nm -1324nm |

| Maximum zero dispersion wavelength dispersion slope | ≤0.092 ps /(nm2.km) |

| 1288nm ~ 1339nm dispersion | ≤3.5 ps /(nm.km ) |

| 1271nm ~ 1360nm dispersion | ≤5.3 ps /(nm.km ) |

| 1480nm ~ 1580nm dispersion | ≤20.0 ps /(nm.km ) |

| 1550nm dispersion | ≤18ps/(nm.km ) |

| 1310nm mode field diameter | 9.2um±0.5um |

| 1550nm mode field diameter | 10.4um±0.8um |

| Fiber cutoff wavelength (λcc ) | ≤1260nm

|

5. Technical data sheet | Technical Data Sheet | Tensile strength | Long term | 75N | Short term | 280 N |

| Flattening force | Long term | 1000N/100mm | Short term | 2000N/100mm |

| Minimum bending radius | Static state | 85 mm | Dynamic | 170mm |

| Storage temperature | -20 ℃ - 60 ℃ |

| Weight | 249kg/km

|