GYDTY53

Request a Quote

, GYDTY53

Application:

Long distance communication, communication between stations, and applications requiring high mechanical strength.

Features:

Double protective layers provide excellent resistance to impact

Metallic central strength member (phosphate steel wire)

PE inner sheath

Double plastics-coated steel tape—PE bounded outer sheath

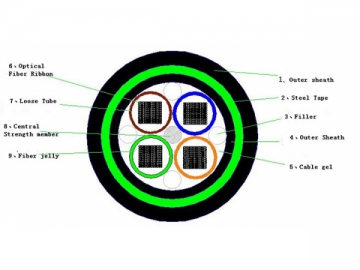

1. Cable Construction

Cable cross-section

Direct-burial cable 576C G652D

2. Cable Specification

2.1 Fiber and Loose Tube Color Code: | No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color | Blue | Orange | Green | Brown | Grey | White |

| No. | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Red | Black | Yellow | Purple | Pink | Aqua |

| CABLE DESCRIPTION | GYDTY53 |

| Fiber capacity | 576 |

| Fiber per tube | 144 |

| No. of fillers | 4 |

| Outer diameter (mm) of cable approx. | 25 |

| Cable weight (kg/km) approx. | 567 |

| Min. bending diameter (dynamic) | 12.5 times cable diameter |

| Min. bending diameter (static) | 25 times cable diameter |

| Tensile performance (N) (short term) | 3000 |

| Crush (N/100mm) (short term) | 3000 |

| Transportation and storage temperature ( ℃ ) | -40 ~ 70 |

| Installation temperature ( ℃ ) | -15 ~ 60 |

| Operation temperature ( ℃ ) | -20 ~ 70 |

3. Characteristic of Optical Fiber

3.1 The properties of single mode optical fiber (ITU-T Rec. G.652D): | Mode field diameter @1310nm | 9.3±0.4um |

| Cladding diameter | 125.0± 1um |

| Attenuation coefficient @ 1310 nm | ≤0.35dB/km |

| @ 1383 nm | ≤0.35dB/km |

| @ 1550 nm | ≤0.22dB/km |

| @ 1625nm | ≤0.24dB/km |

| Core concentricity error | ≤0.5um |

| Cladding non- concircularity | ≤ 1.0% |

| Cable cutoff wavelength | ≤1260 nm |

| Point discontinuity | ≤0.05dB |

| Macro-bend induced attenuation | |

| 100 turns, 30mm radius @1550n/1625m | ≤0.1dB |

| Max. individual fiber | ≤0.2 ps/km1/2 |

| PMDQ | ≤0.1 ps/km1/2 |

| Refractive index @1310nm | 1.466 |

| Zero-dispersion wavelength | 1300 ~ 1324 nm |

| Zero-dispersion slope | ≤ 0.092 ps /(nm².km) |

| Chromatic dispersion coefficient | |

| @ 1310 nm | ≤3.5ps/(nm. km) |

| @ 1550 nm | ≤18ps/(nm. km) |

| @ 1625 nm | ≤22ps/(nm. km) |

| Primary coating diameter | 250±15um |

| Proof test level | 100 kpsi (=0.70 Gpa ), 1% strain |

| Coating strip force (peak value) | 1.3~8.9N |

| Fiber curl (radius) | ³ 4 m |

4. Mechanical & environmental features

| Item | Test Method | Requirements |

| Tensile performance | IEC 60794-1-2-E1 Load: 3000N Cable length under tension: Not less than 50m. Duration of load sustained: 1min. Velocity of transfer device: 10mm/min | The maximum increase in attenuation less than 0.1dB, and total fiber strain less than 0.33% under rated tensile load. No change in attenuation after test at 1550nm. Under visual examination without magnification, no damage to the sheath or to the cable elements after test. |

| Crush | IEC 60794-1-2-E3 Load: 3000N Duration of load: 1min | The increase in attenuation less than 0.1 dB at 1550 nm. Under visual examination without magnification, no damage to the sheath or to the cable elements. The imprint of the striking surface on the sheath is not considered mechanical damage. |

| Impact | IEC 60794-1-2-E4 Impact energy: 5J Number of impacts: 5, each at 3 different places spaced not less than 500mm apart. Height: 1m | The increase in attenuation less than 0.1 dB at 1550 nm. Under visual examination without magnification, no damage to the sheath or to the cable elements. The imprint of the striking surface on the sheath is not considered mechanical damage. |

| Bend | IEC 60794-1-2-E11A £ Mandrel diameter: 25times cable diameter Turns:10 Cycles:5 | No change in attenuation at 1550nm after test. Under visual examination without magnification, no damage to the sheath or to the cable elements. |

| Repeated bending | IEC 60794-1-2-E6 Bending radius: 20 times cable diameter Cycles: 30 Load: 150N Duration of cycle: Approximately 2s. | No change in attenuation at 1550nm after test. Under visual examination without magnification, no damage to the sheath or to the cable elements |

| Torsion | IEC 60794-1-2-E7 Cycles:10 Length under test: 1m Turns: ± 180° Load:150N | No change in attenuation at 1550nm. Under visual examination without magnification, no damage to the sheath or to the cable elements. |

| Temperature cycling | IEC 60794-1-2-F1 Sample length: at least 1000m Temperature range: -20 ℃ ~ 70 ℃ Cycles: 2 Temperature cycling test dwell time: 12 hours | No change in attenuation at 1550nm after test. |

| Water penetration | IEC 60794-1-2-F5B Time: 24 hours Sample length : 3m Water height: 1m | No water leakage |

| Compound flow | IEC 60794-1-2-E14 Sample count:5 Sample length:300 ± 5 mm, Remove length: 130 ± 2,5 mm, Time: 24h | No filling compound dripped. |

| Other parameters meet standards | According to IEC 60794 ,YD/T 901-2009 | |

Related products

Send Message

Most Recent

More

Other Products