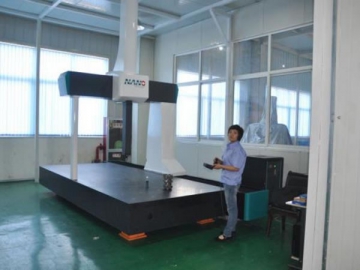

Bridge CMM, COX N Series

If our Micro series CMM can not meet your requirements for measuring precision, the COX N series machine will be a great choice. This high-end series bridge coordinate measuring machine made by NANO is designed for higher precision that is obtained by means of more precise measuring range, optimized air bearings, advanced air bearing vibration reduction technology and more stringent configuration of all components.

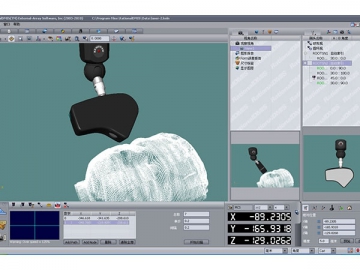

Based on unique triangle beam design, the 3D CMM comes with lower center of gravity and thereby deliver superior motion performance. Provided with RENISHAW PH20 5-axis touch-trigger probe and 5-axis control system, its measuring efficiency is improved by 300%, and it can realize synchronous movement with the axes, thus considerably reducing dynamic deviation and ensuring perfect measuring performance.

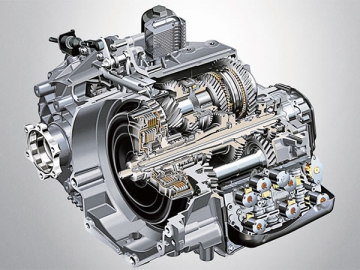

This series bridge coordinate measuring machine takes prides in handling all kinds of measurement and dimensional inspection tasks. For example, it can realize high precision dimensional inspection on box-type workpieces, and precision measurement to the parts with complex geometrical shapes such as turbine blades, gears, screw compressor rotors, etc.

Application fields: This is high precision, high efficiency bridge type measuring equipment designed for aviation, aerospace, and micro mechanical engineering fields.

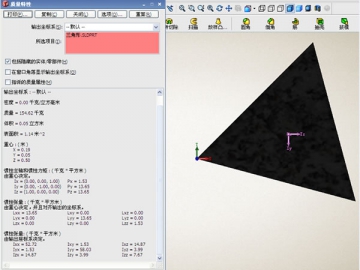

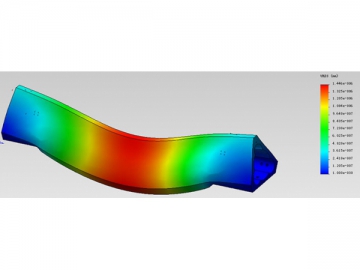

1. The coordinate measuring machine is designed using advanced finite element method (FEM) and mathematical modeling approach. Through optimization of parameters and design schemes, modeling error is minimized. This produces strong structure rigidity, small geometry error, and high precision, performance and stability.

2. On the premise of unchanged quality, the beam in triangular design enhances the motion rigidity along Z-axis and Y-axis directions, increases sectional area, improves the inertia moment and twisting resistance of beam section, and lowers the center of gravity of moving parts. All these help to improving static and dynamic characteristics of the beam and are of great significance for heightening the measuring precision of bridge CMM.

Triangular Beam

Triangular Beam3. Depending on professional design software, the COX N series coordinate measuring machine comes with light weight, high rigidity, small dynamic error, lower center of gravity in motion and smaller movement inertia, therefore ensuring exceptional steady state performance.

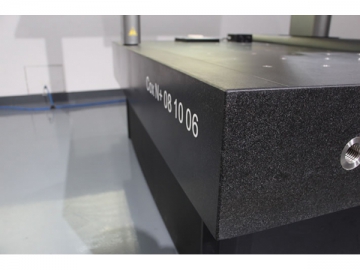

4. Made of high quality granite, three axes feature small thermal expansion coefficient (α=3.0(10-6/K)). Due to identical temperature characteristic, they come with superior temperature stability, high anti-transmogrification performance, great rigidity and small geometrical error in motion. In addition, three axes employ static pressure air bearing guide ways comprised of self-cleaning, pre-loading and high precision air bearings, providing large bearing span, strong anti-sway performance, small resistance, no abrasion and higher stability in motion.

Granite Workbench

Granite Workbench5. Guide ways feature dovetail design which provides high accuracy positioning and reliable steady state performance.

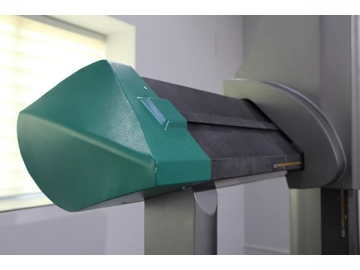

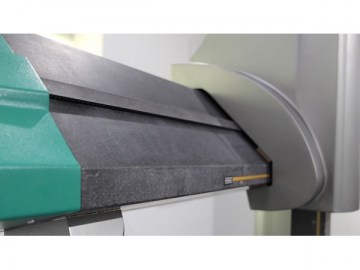

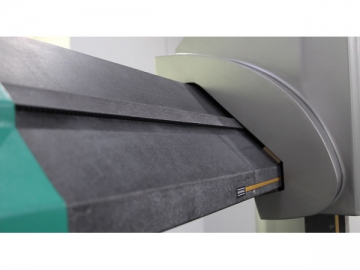

6. This series bridge coordinate measuring machine is proud of the RENISHAW measurement system with reflective metal strip gratings. It has similar thermal expansion coefficient with most workpieces. This guarantees superior repeatability.

RENISHAW Grating Scale

RENISHAW Grating Scale7. In the industrial measurement system, 21 geometric error compensation technologies are used so that measuring precision is dramatically improved.

8. An air cylinder equilibrator system considerably increases the positioning accuracy and stability of Z axis.

9. High precision filtration system from Japan keeps the filtration accuracy of compressed air at 5µm. This can effectively avoid the damage of starting system caused by bad compressed air quality.

- End cover with corner angle design

- Dust prevention solution

- Reasonable limit switch

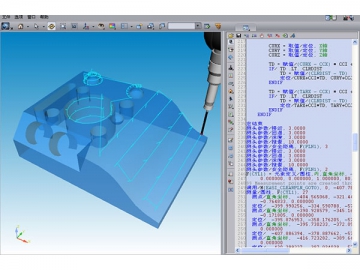

10. The bridge coordinate measuring machine comes with a standard configuration of RENISHAW PH20 5-axis touch-trigger probe and control system. It increases the measuring efficiency by 300%.

11. It uses RATIONAL DMIS, the industry-leading measuring software from the US. With perfect measuring and online function, it can meet customer's exacting demands with a comprehensive measurement solution.

12. Line laser probe is optional for obtaining point cloud data and completing reverse engineering.

| Models | ||

| Indication error (μm) | 1.4 3L/1000 | 1.7 3L/1000 |

| Probing error (μm) | 1.4 | 1.7 |

| Measurement range (mm) | 700X800X600 | 800X1000X600 |

| Dimensions (mm) | - | - |

| Bearing weight (KG) | 1000 | 1200 |