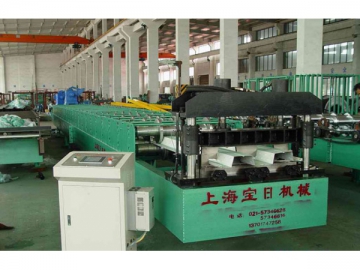

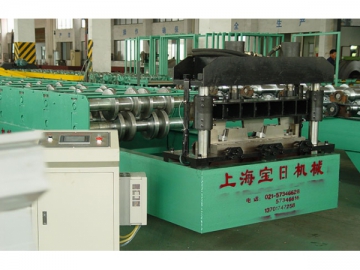

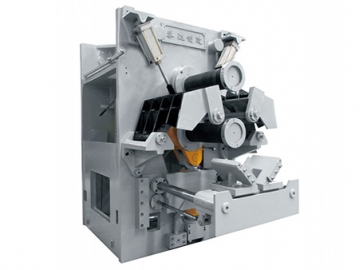

Roll Forming Machine (for Metal Deck)

Baori metal deck roll forming machine features a compact, space saving design that allows easy handling and productive operations.

As coils of color-coated steel strips unfold and pass between counter-rotating roller die sets, they are bent progressively into desired profiles. Usually the steel strip needs to go through tens of roller die sets (technically known as passes) before taking on its final shape.

The entire process is computer controlled. A cycloidal gear reducer is utilized to vary line speeds. The cutting system is hydraulically powered.

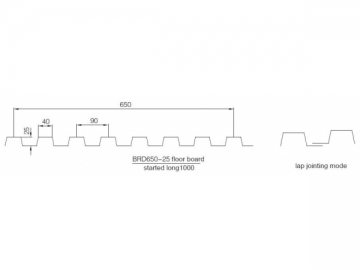

Roll Formed Metal Deck Profile

Technical Specifications

1. Roll forming speed: 0-20m/min

2. Main motor power: 22Kw

3. Cutter motor power: 5.5Kw

4. Hydraulic oil pressure: 10Mpa

5. Power supply: three-phase 380V (4-wire)

6. Steel sheet thickness: 0.5-1mm

7. Passes (number of die sets): 25

8. Shaft diameter: 70-80mm

9. Payoff stand: passive damping force, 5T

10. Dimensions: 15000x1500x1400mm

Roll Former

1. Roll forming dies: 45# hard alloy plating

2. Roller shaft: 45# quenched and tempered, shaft diameter: 75mm

3. Dimensions (L x W x H): 15000mm x 1600 x 1500mm

4. Cutting: chain driven, hydraulically powered

Electrical Control

1. Digital display: Canadian brand Xinje, or PWS6600S-SA Taiwan brand Quanyi

2. PLC: Canadian brand Xinje, or VH-28MR Taiwan brand VIGOR

3. VFD: Japanese brand YiNeng and VFD-M Taiwan brand DELTA

4. Encoder: OVW2-20MHC-2000 Japanese brands, measurement range (0-10m)

5. Stepless speed adjustment, automatic auto-to-length and error correction

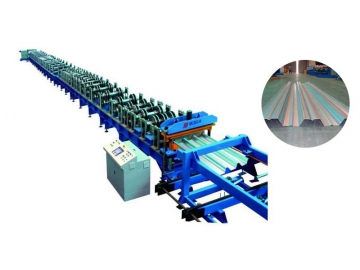

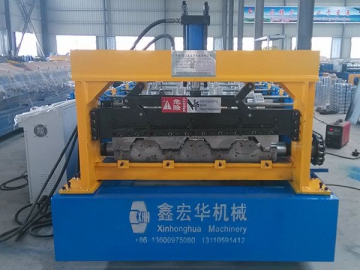

Automatic Metal deck Roll Former

Different metal deck profiles may require different roller former configurations. If customers need to know the exact price quote, please kindly send us a sample of metal deck your customers require.

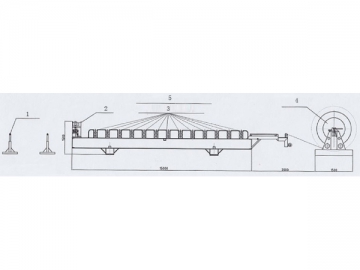

Here is the design drawing for a metal deck roll forming machine we've customized for a customer.

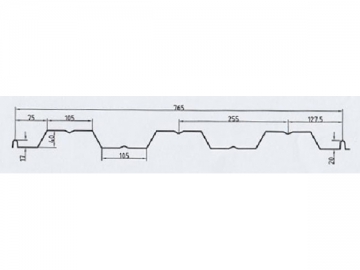

BRD765-40 Metal deck Profile, requiring 18~20 passes

1. Runout table,2. cutting system,3. roller die sets (18~20 passes),4. payoff stand, 5. single-layer roll former schematics

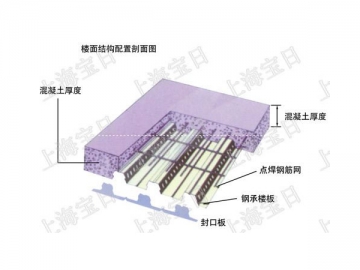

Metal Deck Profile

Steel plate thickness: 0.25-0.5mm

Steel plate width: 1000mm

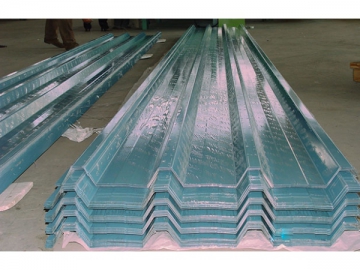

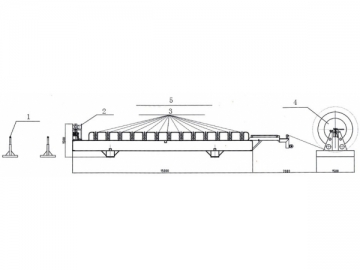

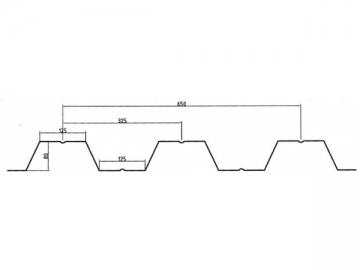

BRD1250-80-650 Curved Plate ---22~24 passes

1. Runout table,2. cutting system,3. roller die sets (22~24 passes),4. payoff stand, 5. single-layer roll former schematics

Metal Deck Profile

Steel plate thickness: 0.4-0.45mm

Steel plate width: 1250mm