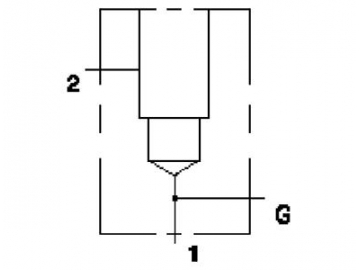

Orifice Flange

Installed in a closed pipeline, orifice flange is used to test the flow rate of fluid, gas and steam just like a throttling gear. Standard orifice plate is a metal plate with a round hole. Round-hole wall is perpendicular to the front face of orifice plate. During installing, axis of the plate and the related pipe should be concentric. The orifice flange is fastened on a pipe through a pair of lugs on it. The flange consists of a plate with a hole in center, a metering device and square margin and Jack screws, which are very easy to dismantle. Two pressure taps are respectively insert ed into the lugs to measure pressure difference of the hole on the plate.

Available Sizes

1"~24", DN25~DN600

Standards

ASME B16.36-2006

Raw Materials

Carbon steel: A105

Alloy steel: A182 F 1-F 2-F 5-F 9-F 10-F 91-F 92-F 122-F 911-F 11-F 12-F 21-F 22

Stainless steel: A182 304-304H-304L-304N-304LN 316-316H-316L-316N-316LN 321-321H 347-347H

Low-temperature steel: A522 A707 Grade L 1-L 2-L 3-L 4-L 5-L 6-L 7-L 8

High-performance steel: A694 F 42-F 46-F 48-F 50-F 52-F 56-F 60-F 65-F 70

Pressure Grade

American System: CLASS 150, CLASS 300, CLASS 400, CLASS 600, CLASS 900, CLASS 1500, CLASS 2500

Flange Facing

American System: Flat Face (FF), Raised Face (RF). Tongue Face (T), Groove Face (G), Female Face (F), Male Face (M), Ring Joints Face (RJ)

Producing Process

Cutting of Raw Material --- Die Forging --- Machining

Application

The flange is widely used in many areas such as power generation plant, petroleum industry, natural gas system, chemical industry, shipbuilding industry, heating system, paper-making industry, metallurgy industry, etc.