Rotary Drilling Rig

RotaryDrilling Rig

256153_drilling rig3.fw.png

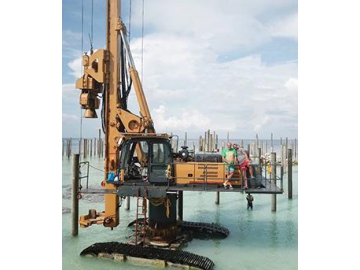

Hengxing Jinqiao Machinery Technology Co., Ltd. is aleading company in the design, manufacturing and sales of rotary drilling rigsand kelly bars for construction in China and all over the world. Our HENQ brandHQR series rotary drilling rigs come in a variety of models to meet differentapplication needs. They are listed as follows: HQR160Z, HQR180D, HQR200D,HQR300Z, HQR360D and HQR 400D. The drilling depth ranges from 10 to 150meters,the hole diameter ranges from 70 to 1000mm, and the output torque ranges from100 to 400KN.m. These rotary drilling rigs are suitable for soil and variousrock hardness level structures.

CATUndercarriage and Up Structure

256153-.jpg

HENGQ’s HQR seres rotary drill rigs have an excellentdesign concept, a reliable operating system, strong power, and self-extendableundercarriage to ensure the operation even in complicated job sites. A heavyhydraulic telescopic crawler is stable and flexible, ideally suited for narrowjob sites. The JVR series rotary drill rig is economic, efficient,environmentally friendly, and features a stable performance.

PowerSystem

256153-0003_r7_c2.jpg

256153-0003_r4_c2.jpg

256153-0003_r5_c2.jpg

256153-0003_r9_c2.jpg

The original CAT EFI engine has a strong power and astrong torque. The electrical fuel direct injection turbo intercooler combinedwith HENGQ’s core technology in the electricity system ensures the engineproduces strong and stable power in each gear. HENGQ’s HQR rotary drill rigssave 10% fuel consumption when compared to the same model of equipment from ourcompetitors, under the same working conditions.

HydraulicSystem

256153-0003_r10_c2.jpg

256153-0003_r11_c2.jpg

The HQR series rotary drill rig uses an internationaladvanced design concept, and uses top internationally known brands for keyparts, hydraulic pilots and scale operation. Advanced main and auxiliaryhydraulic systems achieve flow allocation and sensitivity loading according tooperation demand and the drive function. These features offer a reliable,economic, higher efficiency and save more energy in the construction process.

ElectricitySystem

256153-0003_r2_c4.jpg

256153-0003_r3_c4.jpg

The key parts in the electricity system come from internationallyknown brands based in Germany and Finland. Professional construction machinerycontrollers adjust and control the engine, the pump, main valve, and operationhandle work. At the same time, it is efficient, saves energy and gives off nopollution. The unique design in the intelligent inspection system has theability to check for malfunctions and causes behind the malfunction. A highprecision sensor ensures the drill rig’s precision measurement and inspects theentire work process.

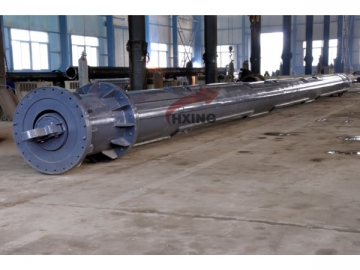

DriveDevice

256153-0003_r6_c4.jpg

256153-0003_r8_c4.jpg

HENGQ’s HQR series rotary drill rig uses aprofessional rotary table that is equipped with a BONGFIGLIOLI or BREVINIreducer. The heavy damping spring and different kinds of multi-level shock absorptiondesigns guarantee a safe operation.

ConstructionMethod

HENGQ has a professional team to support our customersand assist in selecting the right equipment model. The kelly bar and tollconfiguration based on the earth’s structure and construction requirements arechosen in order to improve working efficiency and avoid damage to theequipment.