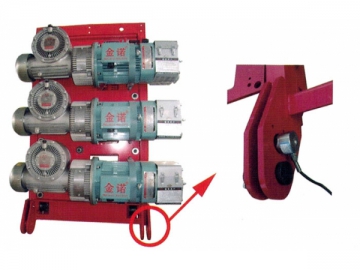

Hoist Motor

Jingya offers rugged, dependable 3-phase asynchronous motors for construction elevators. Unlike previous motor models that use brake bocks to bring the motor to a stop, the newest construction hoist motor uses disc brakes to achieve that function. Built-in electromagnet can do automatic position tracking and adjust its distance from the armature as the brake pads gradually wear down. This enables steady, timely braking operation. Optimized blower vanes and outlet guide vanes make for fast heat dissipation. Design simplicity allows simple operation and easy maintenance, delivering minimized impact force to the construction elevator it is attached to.

1. Our elevator motor offers a choice of three motor base styles, series 132, 160 and 180. Motor horsepower ranges from 5.5kw to 38kw.

2. Both motor and braking system are IP55 rated. Electromagnetic lead wires come with reliable plug and socket connectors or independent wire connectors. Optional brake system warning and protection features automatically find potential brake problems and solve them immediately. The entire braking system is optimized for maximum safety, reliability and stability.

3. Optional temperature control switch keeps motor temperature in check. Micro-controller switch is also available for protection and monitoring.

Frequently Asked Questions

1. What should be done if insufficient braking torque or great torque decrease was found during running or after maintenance?

Check the disc brake first for grease. Clean it up if there is any. Next, tighten the spring to increase its tension. By screwing in 1mm of spring, the pressure increases by 100N. Then check the disc brake for severe wear. If there is, change out the worn disc brake immediately. Finally inspect the mounting plate and armature for serious wear. Replacement is required if obvious wear is found. All personnel, production operations and equipment related to the design and manufacturing of braking system should be closely checked and properly maintained.

2. What should be done if the power went out or equipment failure occurs when the elevator was high up the building?

Cut off the power supply immediately. Pull the handle at the rear of the motor outward. This action will bring the elevator car gently to the ground floor due to gravity.

3. What if the motor vibrates, overheats, gives off a burning smell, or produces abnormal noise?

These problems, for the most part, are caused by damaged bearings. Of course, they might be brought on by other factors as well. When this occurs, stop the motor to find the root cause of it.

It is highly recommended that customers outside China should figure out what voltage they are using. Because we can't provide replacement, technical training, and on-site instruction services to oversea customers, we advise them to buy extra motors for emergency use. It is also best to have spare parts in hand, such as elevator buffers, armatures, disc brakes, brake assembly, and brake pads.