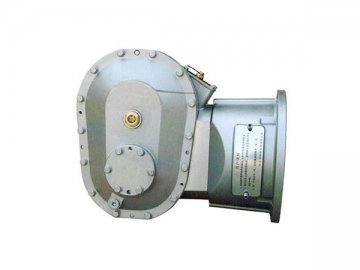

Drive Unit

The drive unit is the heart of a construction hoist, delivering power to moving parts during the elevator's upward and downward movements. A complete power transmission system is typically comprised of an electromagnetic brake motor, gear reducer, motor mounting plate, motor frame, etc. At 1-3t load, the drive unit can deliver a speed ranging from 1 to 60m/min.

The performance and quality of a drive system will directly affect the operating efficiency of the construction elevator. That is why we only source the best electromagnetic brake motor, gear reducer, and safety to construct the drive.

If you've ever been to a construction site or a construction hoist manufacturer in China, chances are that you'll find a Jingya drive unit being installed in the elevator. This widespread presence a tangible testament to the performance and quality of our construction hoist parts. We use high precision equipment to build every drive system, assemble and test it before shipping it out.

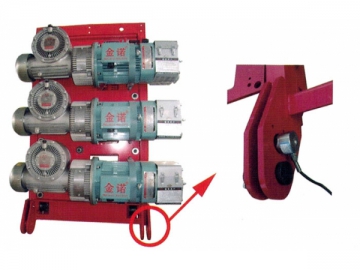

Our decades of manufacturing and testing experience translates into an unmatched ability to deliver reliable, cost-effective motor, speed reducer, and safety system. Our reputation is built on our capability to meet customers' demanding needs. We offer our drive units in a variety of configurations. They can be mounted horizontally or in a tilted manner. They can be single, dual or triple drive systems. They also come with either worm gear reducers or spiral bevel gear speed reducers.

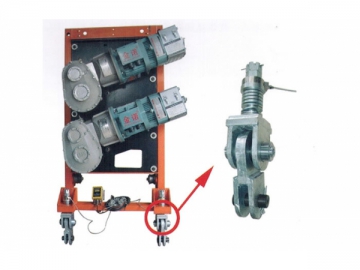

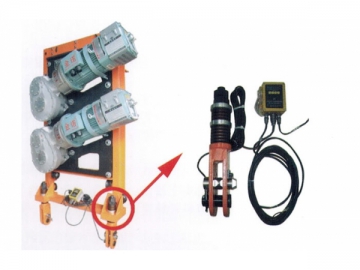

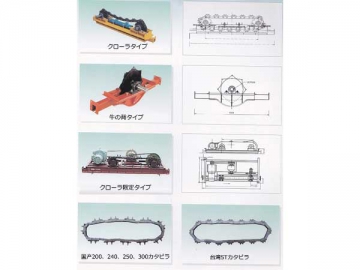

As the drive assembly is directly mounted to the elevator car, connectors or fasteners are needed to make the connection between the two. Conventional connection method is by means of a gusset plate with a hole for the insertion of a large pin. It is a rigid pinned connection that facilitates installation and maintenance but transfers much impact force to the elevator car thereby creating noise and affecting the overall stability during startup and braking.

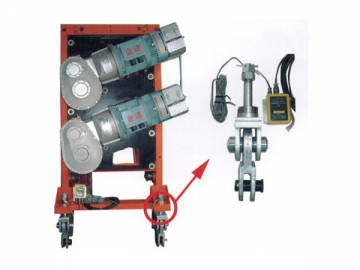

Considering the many disadvantages of a rigid connection, we've developed a flexible connection that allows easy adjustment along X, Y, and Z axes. The flexible joint prevents uneven load distribution that might lead to improper gear engagement causing resistance to the elevator's up and down movement. A flexible connection also means less power consumption, minimized wear, and reduced impact on the elevator car during starting and stop.

Different drive units may vary in power transmission efficiency, including 2 x 11kw, 2 x 15kw, and 3 x 11kw. Previously almost all drive systems of SC series were triple-drive units, though dual-drive models were available as well with counterbalance weights. Now our dual-drive systems do not use counterbalance weights but come with a VFD for speed adjustment. Both dual drive and triple drive have their pros and cons, but they both save energy and allow adjustment of starting torque. Some dual-drive systems can't take heavy loads. So you would think that a trip-drive is better than a dual-drive because it has one more motor, right? Not exactly. The triple-drive loses 40% of its power during transmission through the worm gear reducer. So a 11kw triple-drive delivers only 11KW x 3 x 60%=19.8kw of power.

A dual-drive system, however, enables higher power transmission efficiency by using both straight and helical teeth gears. During a typical braking operation, the drive delivers 95% efficiency. Suppose one drive unit produces 13kw of power, a dual-drive system yields more power, coming to 13KW x 2 x 95%=24.7KW. It is simple maths, which tells us a dual-drive unit is safer and more powerful than a trip-drive. In terms of energy saving, the former saves 30% more power, is easier to maintain and lasts longer than the latter. The right drive system configuration should be chosen based on user habit, installation and maintenance convenience.