Iron Core Oil Immersed Transformer

Request a Quote

Overview

This iron core oil immersed transformer series consists of three-phase distribution transformers with 3D wound cores for high efficiency operation. Compared with series S9, 80% of no-load currents and 30-40% of no-load loss can be decreased. Theses power distribution components are applicable for the power supply and lighting systems of agricultural, mineral, petrochemical and other industrial fields.

Product Features

| Product Item | Three-dimensional volume iron core oil-immersed transformer | Folding iron core oil-immersed transformer |

| Material Saving | Waste-free processing, that is when suit cutting, material utilizing rate is 100% and can save the silicon steel sheet using quantity by 25~30% and copper using quantity by 5~8%. | Material utilizing rate of silicon steel sheet is not high and waste materials are higher. |

| Loss and no-load current | Three-dimensional volume iron core three-phase magnetic circuit without seam, magnetic flux direction is completely consistent with silicon steel sheet crystal orientation, substantially reduce no-load loss and no-load current. | There are a lot of air gaps formed by seams in magnetic circuit, this kind of air gaps increase the reluctance of magnetic circuit, and thus increase the losses and no-load current. |

| Balance of three phase | Three-dimensional volume iron core are formed by three same single frames. Three core limbs are arranged in stereo by an equilateral triangle, three magnetic circuits’ length is consistent and also the shortest, the loss of three core limbs is consistent and so the three phase is balanced. | Not balanced |

| Third harmonic | Reduced | Not reduced |

| Electromagnetic intensity | Low | High |

| Anti-short circuit ability | Strong | Common |

| Production efficiency | There are 5-6 process less than folding iron core, so production efficiency is higher and quality is more stable. | Low |

| Volume | A small covering area | Large |

| Guard against theft | The iron cores are not easily accessed without professional tools. | Resistance against theft is not high. |

Technical Parameters

S13-M.RL-30~1600/10 New energy-saving type three-dimensional volume iron core oil-immersed transformer(high quality silicon steel sheet)

| Rated Capacity | Vector Group | Voltage Combination (KV) | No-load Current | No-load Loss | Load Loss | Short Circuit Impedance | |

| High Voltage | Low Voltage | ||||||

| (KVA) | (H.V.) | (L.V.) | % | W | (75 ℃ )W | % | |

| 30 | Dyn11 Yzn11 Yyn0 | 10 ± 5% 10 ± 2X2.5% | 0.4 | 0.30 | 80 | 630-600 | 4.0 |

| 50 | 0.24 | 100 | 910-870 | 4.0 | |||

| 80 | 0.22 | 130 | 1310-1250 | 4.0 | |||

| 100 | 0.21 | 150 | 1580-1500 | 4.0 | |||

| 160 | 0.19 | 200 | 2310-2200 | 4.0 | |||

| 200 | 0.18 | 240 | 2730-2600 | 4.0 | |||

| 250 | 0.17 | 290 | 3200-3050 | 4.0 | |||

| 315 | 0.16 | 340 | 3830-3650 | 4.0 | |||

| 400 | 0.16 | 410 | 4520-4300 | 4.0 | |||

| 500 | 0.16 | 480 | 5410-5100 | 4.0 | |||

| 630 | 0.15 | 570 | 6200 | 4.5 | |||

| 800 | 0.15 | 700 | 7500 | 4.5 | |||

| 1000 | 0.14 | 830 | 10300 | 4.5 | |||

| 1250 | 0.13 | 970 | 12000 | 4.5 | |||

| 1600 | 0.12 | 1170 | 14500 | 4.5 | |||

S11-M.RL-30~2500/10 Energy-saving type three-dimensional volume iron core oil-immersed transformer (Common silicon steel sheet)

| Rated Capacity | Vector Group | Voltage Combination (KV) | No-load Current | No-load Loss | Load Loss | Short Circuit Impedance | |

| High Voltage | Low Voltage | ||||||

| (KVA) | (H.V.) | (L.V.) | % | W | (75 ℃ )W | % | |

| 30 | Dyn11 Yzn11 Yyn0 | 10 ± 5% 10 ± 2X2.5% | 0.4 | 0.33 | 100 | 630-600 | 4.0 |

| 50 | 0.30 | 130 | 910-870 | 4.0 | |||

| 80 | 0.27 | 180 | 1310-1250 | 4.0 | |||

| 100 | 0.26 | 200 | 1580-1500 | 4.0 | |||

| 160 | 0.24 | 280 | 2310-2200 | 4.0 | |||

| 200 | 0.23 | 340 | 2730-2600 | 4.0 | |||

| 250 | 0.22 | 400 | 3200-3050 | 4.0 | |||

| 315 | 0.21 | 480 | 3830-3650 | 4.0 | |||

| 400 | 0.21 | 570 | 4520-4300 | 4.0 | |||

| 500 | 0.20 | 680 | 5410-5100 | 4.0 | |||

| 630 | 0.20 | 810 | 6200 | 4.5 | |||

| 800 | 0.19 | 980 | 7500 | 4.5 | |||

| 1000 | 0.18 | 1150 | 10300 | 4.5 | |||

| 1250 | 0.17 | 1360 | 12000 | 4.5 | |||

| 1600 | 0.16 | 1640 | 14500 | 4.5 | |||

| 2000 | 0.15 | 2250 | 18500 | 4.5 | |||

| 2500 | 0.15 | 2400 | 24000 | 4.5 | |||

S11-M.RL-30~1600/10 Energy-saving type three-dimensional volume iron core oil-immersed transformer(high quality silicon steel sheet)

| Rated Capacity | Vector Group | Voltage Combination (KV) | No-load Current | No-load Loss | Load Loss | Short Circuit Impedance | |

| High Voltage | Low Voltage | ||||||

| (KVA) | (H.V.) | (L.V.) | % | W | (75 ℃ )W | % | |

| 80 | Dyn11 Yzn11 Yyn0 | 10 ± 5% 10 ± 2X2.5% | 0.4 | 0.27 | 180 | 1250 | 4.0 |

| 100 | 0.26 | 200 | 1500 | 4.0 | |||

| 160 | 0.24 | 280 | 2200 | 4.0 | |||

| 200 | 0.23 | 340 | 2600 | 4.0 | |||

| 250 | 0.22 | 400 | 3050 | 4.0 | |||

| 315 | 0.21 | 480 | 3650 | 4.0 | |||

| 400 | 0.21 | 570 | 4300 | 4.0 | |||

| 500 | 0.2 | 680 | 5100 | 4.0 | |||

| 630 | 0.2 | 810 | 6200 | 4.0 | |||

| 800 | 0.19 | 980 | 7500 | 4.0 | |||

| 1000 | 0.18 | 1150 | 10300 | 4.5 | |||

| 1250 | 0.17 | 1360 | 10200 | 4.5 | |||

| 1600 | 0.16 | 1640 | 14500 | 4.5 | |||

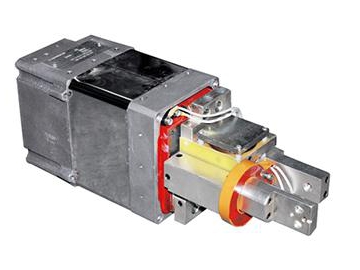

Product showcase

Applications

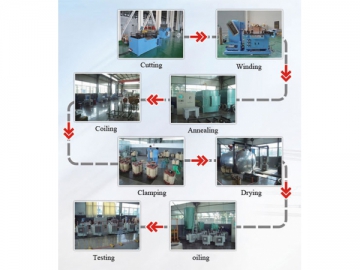

Production process

Product process

Product processRelated products

Send Message

Other Products

Most Recent

More

Other Products

Videos