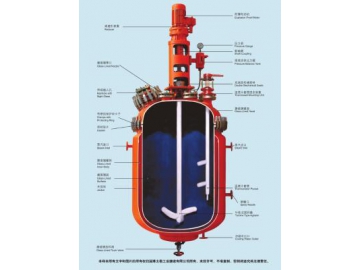

Glass-Lined Reactor, Electric Heating Type

Main Features

1. The electric heated glass-lined reactor produced by Taiji is characterized by rapid heating property, excellent resistance to high temperature and corrosion, great hygienic performance, no environmental pollution, ease of use, etc.

2. It is a new type of glass lined process equipment manufactured on the basis of state of the art technologies both at home and abroad. It finds extensive applications in pharmaceutical, chemical, food, natural seasoning, food additives, light industry and other fields.

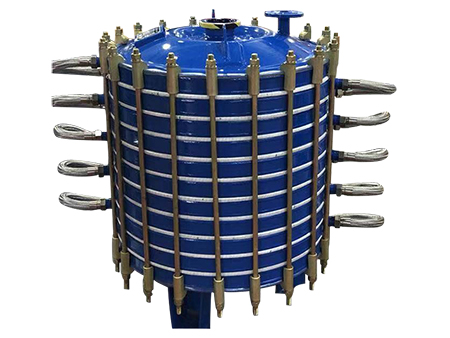

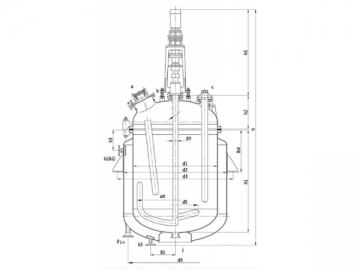

3. The industrial reactor consists of body, cover, agitator, jacket, heating tube, support and drive unit, sealing unit, etc. Materials and nozzles can be determined according to customer's process requirements. We also design and make non-standard reactor to customer's needs.

4. Our electric heating type glass lined reactor applies the TJ09 high performance enamel that is coated on the internal surface of the reactor by sophisticated enameling technology, ensuring excellent resistance to corrosion, mechanical shock and sharp temperature variation, and remarkable durability.

5. At Taiji, we offer a wide range of electrically heated glass lined reactors that are available in all kinds of specifications. Models include K50L, K100L, K200L, K300L, K500L, K1000L, K1500L, K2000L, K3000L, K4000L, K5000L, etc.

Working Principle

The glass lined chemical reactor uses an electric heating bar to heat the heat transfer oil in the jacket. As the temperature is heated to a desired level, the temperature measure and control instrument that is used to control the electric heating bar will shut it down to keep a constant temperature.

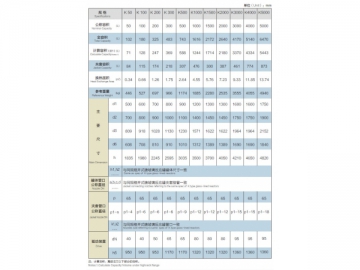

| Internal Vessel | Jacket | |

| Design Pressure (MPa) | 0.4/0.6/1.0 | ATM |

| Design Temperature ( ℃ ) | -19 ℃ /200℃ | -19 ℃ /200℃ |

| Unit: mm | ||||||||||||

| Specifications | ||||||||||||

| Nominal Capacity (L) | 50 | 100 | 200 | 300 | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | |

| Total Capacity (L) | 102 | 180 | 325 | 483 | 743 | 1616 | 2172 | 2640 | 4170 | 5140 | 6470 | |

| Calculated Capacity(Notes 1) (L) | 71 | 128 | 247 | 369 | 588 | 1244 | 1714 | 2180 | 3370 | 4334 | 5443 | |

| Jacket Capacity (L) | 84 | 115 | 174 | 218 | 307 | 476 | 300 | 387 | 461 | 774 | 73 | |

| Heat Exchange Area ( ㎡ ) | 0.34 | 0.66 | 1.26 | 1.75 | 2.64 | 4.55 | 5.76 | 7.23 | 9.33 | 11.85 | 13.74 | |

| Reference Weight (kg) | 446 | 527 | 697 | 966 | 1174 | 1885 | 2280 | 2535 | 3555 | 4055 | 4940 | |

| Main Dimension | d1 | 500 | 600 | 700 | 800 | 900 | 1200 | 1300 | 1300 | 1600 | 1600 | 1750 |

| d2 | 700 | 800 | 900 | 1000 | 1100 | 1400 | 1450 | 1450 | 1750 | 1750 | 1900 | |

| d3 | 809 | 918 | 1028 | 1130 | 1230 | 1571 | 1622 | 1622 | 1964 | 1964 | 2152 | |

| d6 | 608 | 708 | 810 | 910 | 1010 | 1312 | 1389 | 1389 | 1690 | 1690 | 1840 | |

| h | 1835 | 1980 | 2245 | 2595 | 3035 | 3500 | 3700 | 4050 | 4210 | 4650 | 4820 | |

| h1, h2… | Same as the specs of K type glass-lined reactors | |||||||||||

| Nozzle DN | a, b, c, d… | Jacket connecting nozzles referring to the same specs of K type glass-lined reactors | ||||||||||

| Jacket Nozzle DN | p | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 |

| p1-n | p1-4 | p1-6 | p1-6 | p1-6 | p1-9 | p1-12 | p1-12 | p1-12 | p1-15 | p1-15 | p1-18 | |

| k1, k2… | Nozzles size referring to same specs of K type glass-lined reactors | |||||||||||

| Drive | DN | 40 | 40 | 50 | 65 | 65 | 80 | 80 | 80 | 95 | 95 | 95 |

| h5 | 950 | 950 | 953 | 1170 | 1170 | 1320 | 1320 | 1320 | 1360 | 1360 | 1360 | |

| Notes 1: Calculated Capacity: Volume under highneck flange. | ||||||||||||