Combine Harvester, RF40

RF40 is the preferred crawler-type harvester for large fields, owing to its advantages such as high operating efficiency, good adaptability, excellent lodging effect and integrated functions.

Operating condition: paddy field and dry farmland; applicable to the rice, soybean, wheat, oilseed and other grains.

Applicable region: Asia Pacific, Europe and America, Latin America, Africa and other regions.

1. High operating efficiency (high harvesting efficiency)

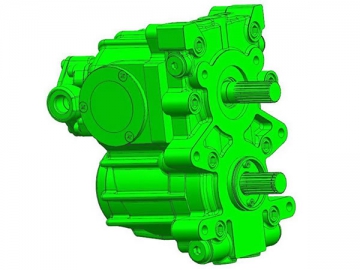

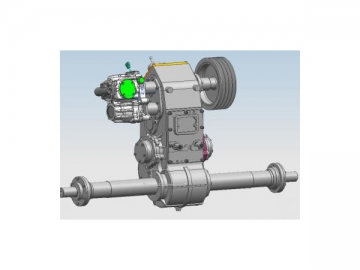

The large-displacement HST imported from Japan, the reinforced gearbox, the optimized gear ratio design and the high drive torque ensure the good passing performance in the muddy field.

The widened cleaning screen with effective width up to 1,390mm is used so among the vehicles of this kind, its cleaning screen is widest. The large cleaning screen reduces the cleaning loss during fast harvesting.

2. Good operating effect (performance)

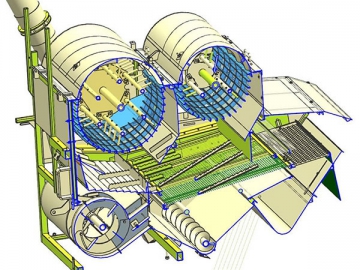

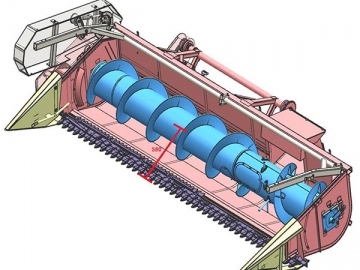

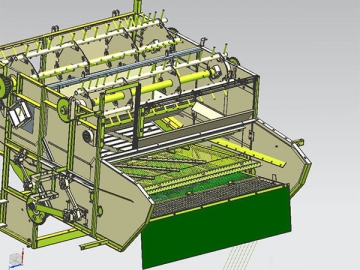

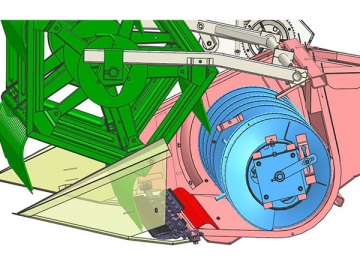

Header and conveyer: Considering the waterlogging of rice in autumn and serious lodging in the high latitude area, the header and conveyer system is optimized.

Considering the height of rice straw, the relative positions of winder, feeding auger and cutter are optimized, and the distance from cutter to feeding auger is increased to 580mm, avoiding the ear falling of high-straw or laid crops and reducing the loss caused by the header.

The arced feeding plate is arranged in the front of header body, which effectively eliminates the triangle dead area formed by the header body, feeding auger and winder so that the crops will not heap up in the front of header, ensuring the successful feeding and avoiding the straw collection and ear falling.

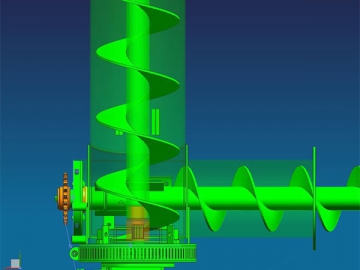

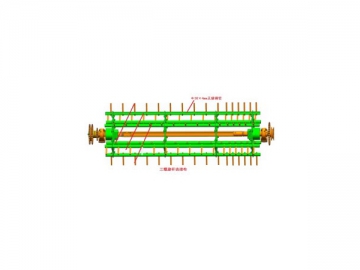

The rack bar at the outlet of first drum is extended, reducing the triangle zone. The material conveying method is changed from grabbing to feeding so that the materials are easy to enter the second drum, ensuring the smoother feeding.

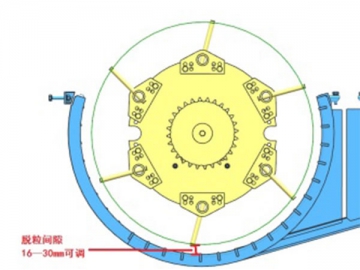

The gap between the threshing drum and the notch board can be adjusted from 16mm to 30mm to change the threshing capacity so the vehicle has the strong adaptability to the rice of different kind and mixture, ensuring the high threshing quality.

The matching between the farm-oriented centrifugal blower and the double-deck vibrating sieve is optimized to ensure the reasonable distribution of longitudinal air flow on the sieve, the uniform transverse air flow on the sieve, the good cleaning effect and the less loss on the sieve.

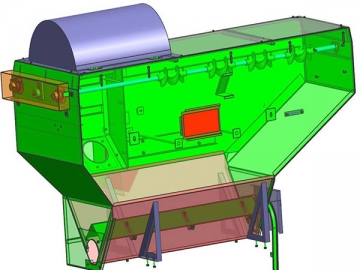

The 2m3 super-large grain bin and the grain distributing auger are used so that the grains can fill the bin fully and effectively and the vehicle can operate continuously for a long period.

3. Improvement of reliability

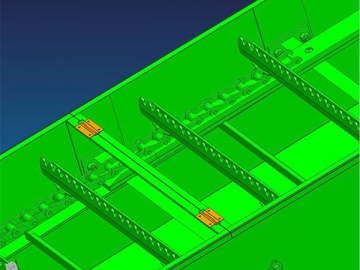

The conveying chain rack is made of 4mm-thick punched steel plate, ensuring the strong deformation resistance and the longer service life.

The threshing rack bard is made of Φ30×4mm reinforced seamless steel pipes, ensuring the strong deformation resistance.

The concave sieve is an integral 16Mn cold-drawn flat-steel grid, which has the higher strength, rigidity, wear resistance, abrasive resistance and corrosion resistance and can process the laid and wet crops.

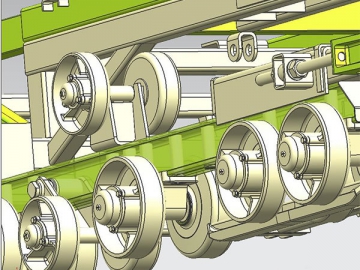

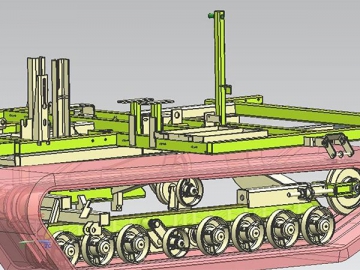

The 450×90×56 crawler with a long service period is used. The wheel train is equipped with 7 sets of trust wheels, ensuring the high carrying capacity and the strong anti-off ability of crawler; the integral cast trust wheel and guide wheel have greatly improve the deformation resistance of wheel train so that the vehicle can pass through the slopes and low banks easily (the wheel train has the high integral strength and good abrasive resistance)

The trust wheel support is of the saddle structure and made of 270-500 cast steel as a whole so it is easy to install, has a high strength and will not affect the strength of vehicle beam. The gap between the bogie beam and the trust wheel is large, avoiding the mud or straw jamming.

The 40-displacement HST imported from Japan (first brand in this trade) is used, which has a big drive torque and a long service life and is easy to operate.

The conveying auger blade of the vehicle is processed with the gaseous carbon-nitriding heat technology, ensuring the high hardness and abrasive resistance of surface and the long service life.

| Technical platform | Double transverse axial-flow drum | ||

| Product series | RF series | ||

| DF/MF290 | |||

| Product model | |||

| Sale identification code | RF40 | ||

| Performance parameters | Vehicle dimension | Length (mm) | 5850 |

| Width (mm) | 3220 | ||

| Height (mm) | 3200 | ||

| Feeding speed (kg/s) | 4.0 | ||

| Gross weight (kg) | 4070 | ||

| Dynamic parameters | Engine manufacturer and specification | Emission standard (number of cylinders) | China State II/I (4 cylinders) |

| Configuration 1 | Lovol Engines1004C-P4T (66kW/2000r/min) | ||

| Configuration 2 | Tianli 4JR3ABL (66kW/2600r/min) | ||

| Configuration 3 | Yuchai YC4A90 (66kW/2300r/min) | ||

| Capacity of fuel tank, L | 110 | ||

| Header parameters | Cutting width, mm | Basic equipment | 2880 |

| Optional equipment | — | ||

| Width of intermediate transmission shaft, mm | 550 | ||

| Auxiliary functions and accessories (inverted intermediate transmission shaft, dust collection fan) | — | ||

| Chassis parameters | Drive axle/ gearbox | Configuration 1 | Lovol axle |

| Configuration 2 | — | ||

| Track distance, mm | 1300 | ||

| Crawler width (mm) x pitch (mm) x number of sections | Configuration | 450×90×56 | |

| Min. ground clearance | 260 | ||

| Drive method of chassis | Configuration | Mechanical | |

| HST model/ displacement | — | ||

| Optional equipment | — | ||

| Steering method | Configuration | hydraulic steering | |

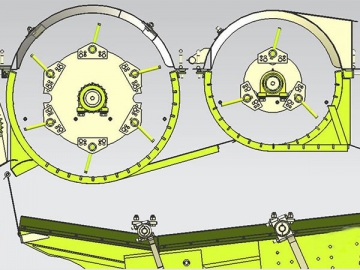

| Cleaning and threshing system | Threshing and separating device | Configuration form | Double transverse axial flow |

| Configuration for wheat and rice | Rod-tooth drum | ||

| Configuration for oilseed | — | ||

| Size of drum, mm | φ564×1365 φ420×1365 | ||

| Type of cleaning sieve | Structure of screen box | Double-deck vibrating sieve | |

| Configuration 1 | — | ||

| Cleaning width, mm | 1390 | ||

| Grain bin and unloading method | Capacity of grain bin | Configuration 1 | Overhead 1.8m³ |

| Configuration 2 | — | ||

| Grain unloading method | Manual pick-up port | — | |

| Simple unloading drum | ● | ||

| hydraulic simple unloading | — | ||

| hydraulic horizontal unloading | — | ||

| hydraulic lifting and rotating unloading | |||

| Battery / voltage | 12V/2×6-QW-100 | ||

| Optional equipment | Lower cutter | — | |

| Chopper | — | ||

| Straw breaker | ● | ||

| Awning | — | ||

| Ordinary cab | ● | ||

| Heated cab | — | ||

| Backup alarm/ grain full alarm | ● | ||