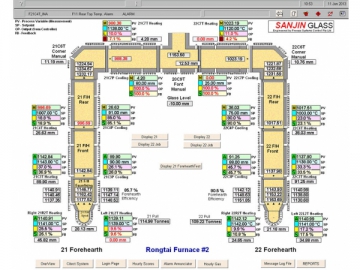

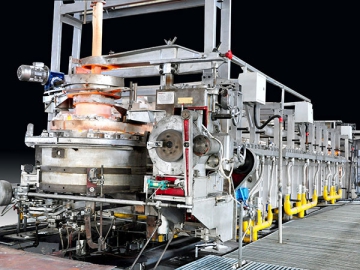

Gas Forehearth

Due to simplified system design, the gas forehearth is provided with a high degree of thermal stability and cooling capability. It delivers increased flexibility and wider tonnage range which are necessary to meet the rapidly changing market demands. As required, the glass making forehearth supports both centerline heating and side heating, providing better control over the glass conditioning process.

Key Features

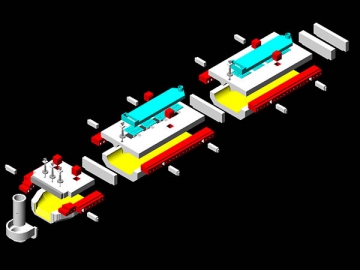

The gas fired forehearth features indirect centerline cooling.

Cooing section partitioning enables preferential side heating.

Central partitioning for the equalizing section allows for independent side firing.

Stable and precise temperature control.

Thermocouples submerged in glass

Specifications of the Gas Forehearth

Channel Width: 18-54 inches (460mm-1350mm)

Tonnage Range: 3 to 150 tons per day (depending on width)

Cooling Mode: Indirect centerline cooling

Control Configuration: Standard PID control over both heating and cooling

Temperature Control Sensors: Thermocouples/fibre optic pyrometers depending on glass type or customer preference

Combustion System Configuration: Pressure or flow sensor for air/fuel ratio control, or designed according to customer preference

Glass Type: The forehearth system is suitable for all glass colors

Indirect Centerline Cooling

Color consistency is important during colored glass production, such as the production of amber and green glass. The gas forehearth’s indirect centerline cooling helps maintain constant redox levels, thus ensuring color consistency.

Indirect cooling effectively prevents cooling air from mixing with the fuel gas, which provides increased thermal efficiency for both heating and cooling systems. The cooling method also boasts no effect on the internal pressure of the forehearth system.

Individual cooling plates placed along the cooling section also allow cooling to be introduced more gradually. This reduces the likelihood of chilling the top glass.

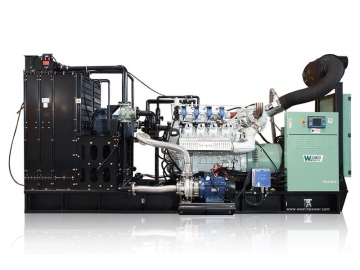

Combustion System

The gas forehearth’s combustion system is designed to work with either LPG or natural gas. Due to the design of venturi mixers and pressure sensing ratio regulators, the manifold pressure is adjustable between 20mm WC and 250mm WC. A combustion system based on flow sensing ratio regulators is available as an option.

Cooling Air Control

The gas forehearth uses individual blowers with variable speed drive controls. The slight increase in capital cost is more than offset by the significant operating energy cost savings.

A Better Forehearth System Design

The advanced gas heated forehearth not only provides improved glass conditioning but, because of the increase in cooling capability, accommodates wider tonnage and gob temperature ranges.