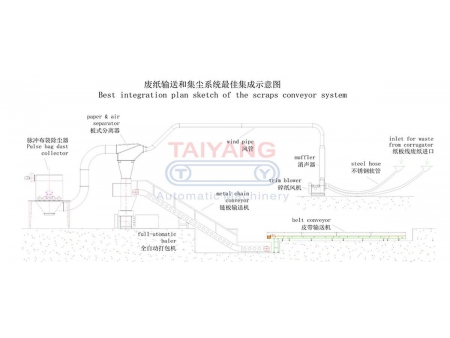

Bottle Handling Conveyor

Linear Conveyor System

Usage

The bottle handling conveyor is designed for automatic bottle arrangement and continuous bottle conveying purposes during glass container production. It can also be used for the same purposes in related industries such as bottle filling, bottle packaging, etc. Synchronous automatic and manual inspection can be realized when detection positions are set on both sides of the straight conveying section.

Technical specifications

Structure of the bottle handling system can be custom designed to meet users’ individual requirements.

Conveyor width (mm): 1200, 1500, 1800, 2100, 2400, 2700, 3000, 3300, 3600, or customized

Voltage: 380V, 50Hz

Linear speed: 10m/Min -20m/Min

Max. liner speed: 20m/Min

Main structure features of the bottle handling conveyor

1. Modular design allows for arbitrary combination between functional units, thus adapting to different plane layout.

2. Relatively independent power and drive systems can satisfy different combining form.

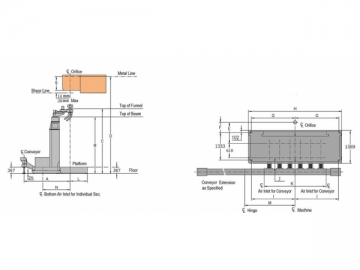

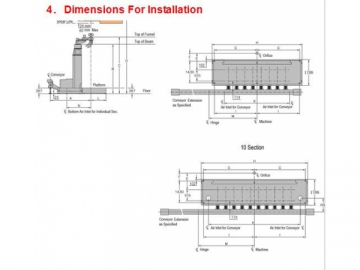

3. The height of conveying chain can be adjusted in the range of 970 - 1050mm.

4. Conveying chain is made of high molecular material with low friction coefficient, and thus delivers high wear resistance.

| -PG | 3 rows, 1 direction |

| -PS | 3 rows, 2 direction |

| -PZ | 4 rows, 1 direction |

| -PGS | multi-rows, 1 direction |

| -PP22 | 6 rows, 2 lines,1 direction |

| -PP27 | multi-rows backward conveying,1 direction |

Circular Conveyor System

This kind of bottle handling conveyor mainly works as the bypass system of glass container inspection machines or manual inspection centers.