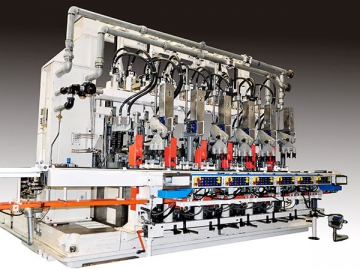

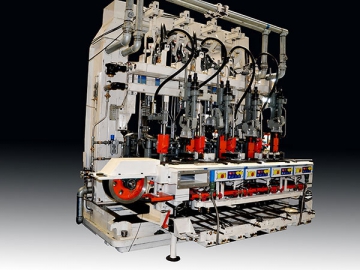

Standard Configurations of the Triple Gob Individual Section Machine

FLEXLINE Control System

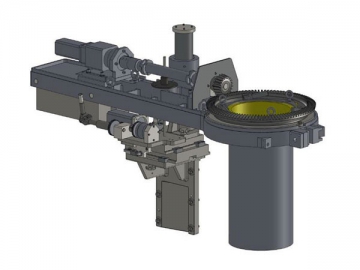

Servo Gob Distributor

New Type of Delivery System

Linkages in Oil System for Blank and Blow Molds

Blank Mold with Protecting Brackets

Quick Change Take-out Tong

Quick Change Blowhead Mechanism

Wide Uprights for Machine

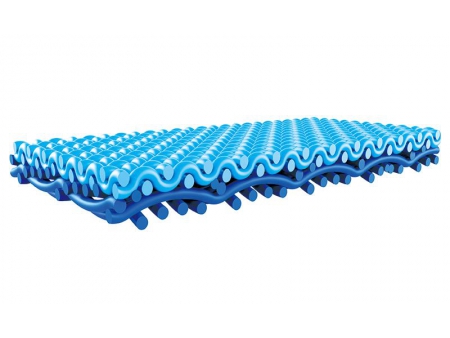

VertiFlow Blow Mold Cooling Mechanism

Bottom Plate Mechanism with Vacuum-Assistant Forming

Quick Change Plunger Mechanism

Conveyor with Silent Chain

Timing and Rationing Automatic Lubrication System

Optional Configurations of the Triple Gob IS Machine

Constant Cushion Invert Mechanism

Servo Electric Invert Mechanism

Constant Cushion Take-out Mechanism

Servo Electric Take-out Mechanism

21# Electro-Pneumatic Valve Block (EPVB)

26# EPVB

Electronic Pusher, Double Horizontal Cylinders

Servo Electric Pusher

On/off Control Blank Mold Cooling Mechanism

Glass Container Forming Methods

Blow and Blow

Press and Blow

Narrow Neck Press and Blow

Glass Container Specifications | Blow and Blow | Press and Blow | Narrow Neck Press and Blow |

| Ware Range |

| Maximum Body Diameter with VertiFlow | 76mm |

| Maximum Body Diameter (Stack Cooling without Vacuum) | 90mm |

| Maximum Body Diameter with Vacuum | 80mm |

| Minimum Height under Finish | 57mm | 40mm |

| Maximum Height under Finish (with VertiFlow) | 301mm | 257mm |

| Maximum Finish Diameter | 48mm | 83mm | 38mm |

Consumptions of the Individual Section Machine | Media | Pressure (Bar) | Consumption per Section Nm3/min |

| Low Pressure Operating Air | 2.1 | 1.0 |

| High Pressure Operating Air | 3.1 | 1.0 |

| High Pressure Air (Pilot Air of EPVB) | 4.0 | 0.003 |

| Forming Air (Blow and Blow) | 3.1 | 1.8 |

| Forming Air (Press and Blow) | 3.1 | 2.6 |

| Vacuum | 150mbar | 0.2 ~ 0.3 |

| Stack Cooling Only | 1200mm H2O | 75 |

| VertiFlow Blowside and Blank Stack | 1200mm H2O | 50 |

| Conveyor | 600 mm H2O | 10 |

| Lubrication Oil | 80 | 1.3L/day |

| Cooling Water | 2.1 | 15L/min |

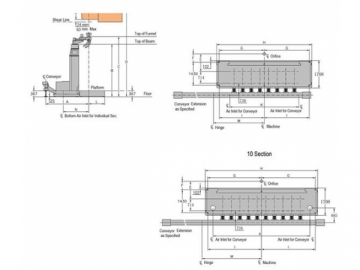

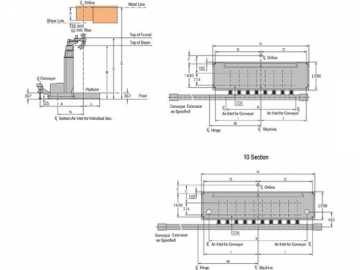

Installation Dimension of the Glass Container Forming Equipment | IS Machine Section Number / Dimension | 4 | 6 | 8 | 10 |

| mm | mm | mm | mm |

| A | 2363 | 2363 | 2363 | 2363 |

| B | 3274 | 3274 | 3274 | 3515 |

| C | Delivery Center Distance 76mm | 3752 | 3752 | 3752 | 3993 |

| Delivery Center Distance 110mm | 3722 | 3722 | 3722 | 3963 |

| D (Recommended) | 5000 | 5000 | 5000 | 5300 |

| E | 1168 | 1168 | 1168 | 1168 |

| F | 568 | 568 | 568 | 568 |

| G | 1730 | 2264 | 2798 | 3332 |

| H | 3660 | 4828 | 5896 | 6964 |

| I | 1716 | 2250 | 2784 | 3318 |

| K | 2306 | 3236 | 4304 | 6010 |

| L (Standard) | 596 | 596 | 596 | 596 |

| L (With Receivers) | 1296 | 1296 | 1296 | 1296 |

| M | 2292 | 2826 | 3360 | 3430 |

| N | 1502 | 1502 | 1502 | 1292 |

| Machine Weight | 16T | 23T | 28T | 44T |