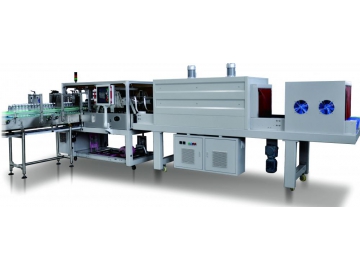

Automatic L Type Shrink Wrapping Machine

Product Introduction

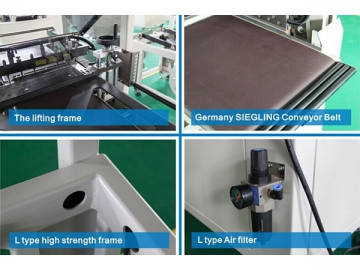

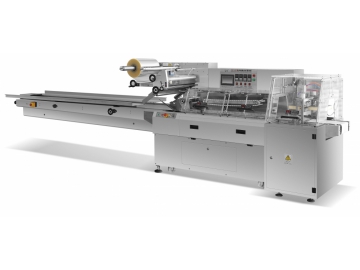

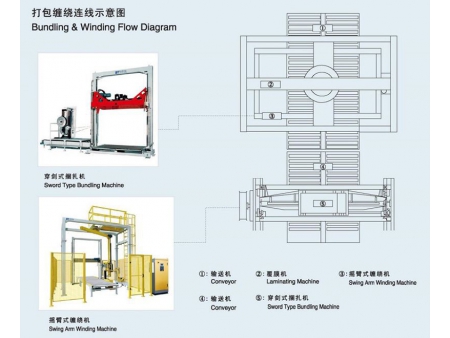

The automatic L type shrink wrapping machine uses an imported PLC automatic program control, safety protection and alarm functions. Each of those features, combined with an easy operation ensure prevention from incorrect packaging. The shrink wrap machine is also equipped with an imported horizontal and vertical detection photoelectric device, making it easy to switch between selections. The automatic shrink wrap machine can also be connected directly to a production line, with no need for additional operators.

Automatic Grade: Automatic

Suitable shrink film: POF

Application: food, cosmetics, stationary, hardware, daily used products, pharmaceutical

Packaging style: L type full closed packing

Kissing connection is optional

| Model | | |

| Max. Packing Size | (L H)≤500 (W H)≤430 (H)≤150 mm | (L)700x(W)400 x(H)200 mm |

| Max. Sealing Size | (L)550x(W)450 mm | (L)1000x(W)450 x(H)250 mm |

| Packing Speed | 30-35 packs/min. | 0-15 m/min. |

| Electric Supply & Power | 220V / 50Hz 1.3 kw | 380V / 50Hz 12 kw |

| Air Pressure | 5.5 kg/cm3 | / |

| Weight | 500 kg | 260 kg |

| Overall Dimensions | (L)1800x(W)800 x(H)1600 mm | (L)1300x(W)700 x(H)1400 mm |

Features:

1. The BTA-450A is an economical, fully automatic L sealer manufactured through our independent research and development. It is widely used in mass production assembly lines, due to its automatic feeding, conveying, sealing and single process shrinking. It has a high working efficiency, and is suitable for products of different heights and widths.

2. The horizontal blade on the sealing component uses a vertical driver, while the vertical cutter uses an advanced international thermostatic side cutter. The sealing line is straight and strong, and will be straight down the middle of the product in order to achieve an excellent sealing effect.

3. Changeover between packaging of different size requirements is easy. Simply rotate the hand wheel to increase the reliability.

4. The machine uses an advanced PLC programmable controller, which is equipped with safety protection and alarm devices. The sealing system has a continuous sealing order with no need for replacement, and maintenance is incredibly simple.

5. The feeding length is controlled through a combination of electric eye detection and a time relay to control the precise film length, and make it easier to control the contraction effect.6. Two groups of vertical and horizontal electric eyes are easy to switch for thin and small packages, easily controlling the contraction effect.

7. The waste material is automatically rolled. A separate motor is used to control and easily remove waste. It is not too loose or too tight, which can cause cracks.

8. The blowing function is automatic.

9. The feeding table and collecting conveyor can be selected according to your demands.

| NO | NAME | BRAND | QTY |

| 1 | Product feeding motor | SESAME (Taiwan) | 1 |

| 2 | discharged motor | SESAME (Taiwan) | 1 |

| 3 | Film unwind motor | SESAME (Taiwan) | 1 |

| 4 | Film pulling motor | SESAME (Taiwan) | 1 |

| 5 | waste film recycling motor | SESAME (Taiwan) | 1 |

| 6 | Cutting cylinder | SHAKO (Taiwan) | 1 |

| 7 | conveyor kissing cylinder | SHAKO (Taiwan) | 1 |

| 8 | Breaker | Schneider (France) | 2 |

| 9 | PLC | OMRON (Japan) | 1 |

| 10 | Temperature controller | OMRON (Japan) | 2 |

| 11 | Time relay | OMRON (Japan) | 3 |

| 12 | Auxiliary relay | OMRON (Japan) | 7 |

| 13 | Solid state relay | OMRON (Japan) | 2 |

| 14 | Vertical sensor | BANNER (banner) | 2 |

| 15 | Horizontal sensor | BANNER (banner) | 2 |

| 16 | Electrical magnet valve | SHAKO (Taiwan) | 2 |

| 17 | Air filter | SHAKO ( Taiwan) | 1 |

| 18 | Approach switch | AUTONICS (Korea) | 1 |

| 19 | Conveyor | SIEGLING (Germany) | 2 |

| 20 | synchronous belt | MITSUBOSHL(Japan) | 2 |

| 21 | Sealing knife | DAIDO (Japan) | 2 |

| Model | | |

| Max. Packing Size | (L H)≤500 (W H)≤430 (H)≤150 | (L)700x(W)400 x(H)200mm |

| Max. Sealing Size | (L)550x(W)450mm | (L)1000x(W)450 x(H)250mm |

| Packing Speed | 30-35 packs/min. | 0-15 m/min. |

| Electric Supply & Power | 220V / 50Hz 1.3 kw | 380V / 50Hz 12 kw |

| Air Pressure | 5.5 kg/cm3 | / |

| Weight | 500 kg | 260 kg |

| Overall Dimensions | (L)1800x(W)800 x(H)1600mm | (L)1300x(W)700 x(H)1400mm |

Terms and Conditions

1.Packaging Details: The Standard Export Wooden Boxes.

2.Terms of Trade: FOB Shanghai.

3.Shipment: By sea.

4.Quality Guarantee: The seller will provide free component parts within 12 months.

5.After-Sales Service Provided: Engineers are available to service machinery overseas.