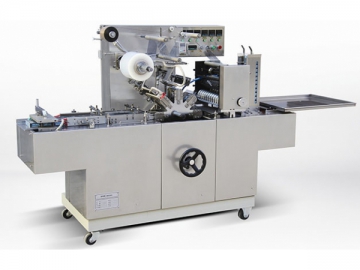

Cellophane Overwrapping Machine, BTB-400

Product Introduction

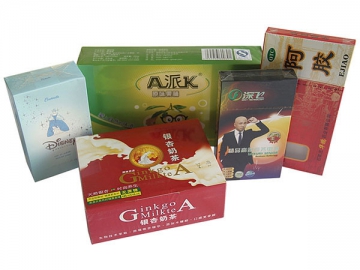

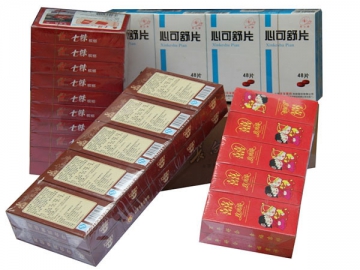

The BTB-400 cellophane overwrapping machine uses a multi-functional digital display and frequency conversion stepless speed regulation, PLC programmed control technology, automatic box feeding and counting, touch screen display, and pneumatic film falling. The work is carried out via a series of cameras in the wrapping machine to drive the different floating links and parts. The overwrapping machine can also be combined with other machines to form a complete production line. This cellophane overwrapping machine is applicable for packaging different single box large items, as well as collective blister packs of multiple piece box items with a gold tear tape.

Automatic Grade: Automatic

Driven Type: Electric

Application: food, cosmetics, stationary, hardware, daily use products, pharmaceutical products

- Single large box or multi-piece boxes

| Packing Material | BOPP film and gold tear tape |

| Packing Speed | 25 ~ 40 packs/min |

| Packing Size | (L)300 x (W)200 x (H)100mm |

| Electric Supply & Power | 220V 50Hz 5.5kw |

| Weight | 800kg |

| Overall Dimensions | (L)2400 x (W)1200 x (H)1800mm |

Features:

1. There is no need to regulate the height of the two work tops on the machine when the mold needs to be replaced. There is also no need to assemble or dismantle the material discharge chains or discharge hopper, which reduces the mold replacement time from 4 hours to 30 minutes.

2. A new double safeguard mechanism is used, preventing damage to spare parts in the event of incorrect wrapping machine operation.

3. A unilateral hand swing device prevents machine vibration, and the prevention of hand wheel rotation during machine operation ensures the safety of the machine operator.

4. A new double rotary film cutter ensures there is no need to mill a blade after multiple years of machine operation. This overcomes obstacles posed by a traditional stationary single rotary film cutting knife that wore down faster

Functions and Options

This cellophane overwrapping machine is equipped with a vertical film blowing structure to ensure the long sealing of the box is more firm. The machine is also applicable for double boxes that are packed side by side, improving the availability and added value of the machine.

| Name | QTY | Model | From |

| CPU | 1 | Siemens | |

| Temperature controller | 2 | Siemens | |

| Touch screen | 1 | Siemens | |

| Extension module | 1 | Siemens | |

| servo motor | 1 | 0.75KW 3000RPM | Taian |

| Servo controller | 1 | | Taian |

| Frequency converter | 1 | | Taian |

| Slot type optical coupler | 6 | omron | |

| Small relay | 6 | omron | |

| Solid state relay | 7 | | Langning |

| Main motor | 1 | Zhengjiang | |

| Film cutting knife | 1 | Zhongmei | |

| bearing | Whole set | Wanma |