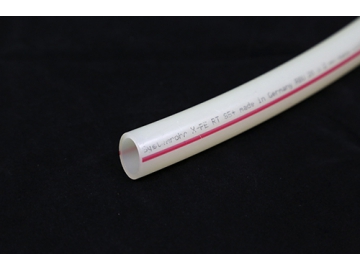

RPAP5 Composite Pipes and Fittings

Product Description

-The RPAP5 composite pipes from Kingbull are pipes with plastic protective layers and allowing hot water of 95℃ and 1.25Mpa to flow through.

-Thickness of the aluminum layer reaches the standards of ASTM, ensuring high bearing capacity. Based on TIG welding, weld joint comes with high strength and small linear expansion coefficient that result in no deformation. With excellent roundness, the floor heating pipe complies with the F1335-04 standard.

-Double heat fusion technique enables the aluminum layer to be completely isolated from the outside environment, thus ensuring excellent resistance to corrosion and up to 50 years service life.

Applications

The RPAP5 composite pipes and fittings are applied in hydronic heating system, radiant heating system and solar heating system for every type of buildings.

Construction

PE-RT, Adhesive, Aluminum, Adhesive, PE-RT

RPAP5 25 RPAP5 25 RPAP5 RPAP5

Male Elbow 45° Elbow 90° Elbow Female Wall Plate Elbow Male Wall Plate Elbow Female Elbow Male Coupling Male Union Female Coupling Female Union Reducing Tee Reducing Elbow, 32×25 Reducing Socket 32×20 Male Tee Female Tee Equal Socket Equal Tee 90° Wall Plate Tee Female Wall Plate Tee Male Wall Plate Tee

Plastic Rounding and Beveling Tool Manual Rounding Tool Pipe Cutter Heat Welding Machine RPAP5 Heat Welding Machine and Die Heads RPAP5 Die Heads

Advantages of Kingbull RPAP5 Composite Pipes and Fittings

1. Meet the requirements for long time use at 95℃ and 1.25MPa; they are suitable for water supply system and heating system in buildings.

2. Pipes and fittings are made using same materials and double heat welding method, ensuring ease of maintenance and no leakage at all.

3. Expansion test for weld joint strength follows the industry standard of 1.13 times expansion. Our standard reaches 1.3 times. So, it is proven that the welding and adhesive performance of our PE-RT pipes is superior.

4. Peeling strength of outer PE-RT coating is up to 60~110N/cm.

5. They pass the test of 5000 times cold and hot water circulation.

6. We introduce world leading PE pipe production line equipped with barrier type screw and IKV forced extrusion system which enable the performance of raw materials to be completely transferred to the pipe.

7. They are manufactured from Imported PE-RT and aluminum of superior performance, using high performance adhesive and state of the art GTAW welding technology.

8. We establish rigorous quality control system, advanced ERP system, anti-conterfeiting logistic sign and barcode management system which are traceable.

9. Production is conducted under the ISO9001 and ISO14001 standards, ensuring high customer satisfaction. Three-class quality control system is set up to ensure 100% qualification of delivered products.

Comparison of Pipes Made Using Butt Welding and Lap Welding:

Composite pipes made using butt welding: Metal pipes with plastic protective layers;

Composite pipes made using lap welding: Plastic pipes with metal shielding layers

| Specifications (mm) | Aluminum layer thickness (mm) | Min. wall thickness (mm) | Plastic layer thickness | |||

| Butt welding | Lap welding | Butt welding | Lap welding | Butt welding | Lap welding | |

| 16 | 0.30 | 0.18 | 2.3 | 1.7 | 2.0 | 1.52 |

| 20 | 0.35 | 0.23 | 2.5 | 1.9 | 2.15 | 1.67 |

| 25 | 0.40 | 0.23 | 3.0 | 2.3 | 1.9 | 2.07 |

| 32 | 0.60 | 0.28 | 3.0 | 2.9 | 2.3 | 2.62 |