Biaxially Orientated Polyamide (BOPA) Film

Cangzhou Donghong Packing Material Co.,Ltd., was founded in Sept. 2003, a branch of Cangzhou Mingzhu Plastic Co., ltd., manufacture prime-quality cast bi-axially oriented polyamide (nylon) film.

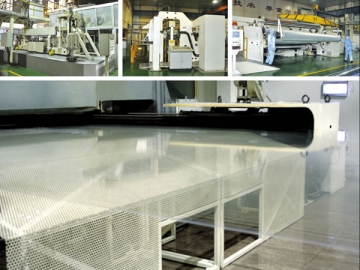

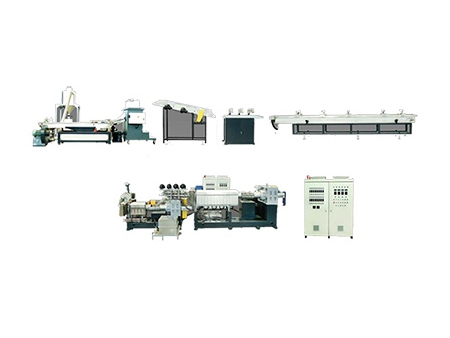

Our first line of BOPA film was formed in 2003. With advanced technology - cast tenter frame simultaneous bi-axially oriented technology, the film has stable quality and excellent performance. The property can meet the request of the customers.

In order to meet the high demand of our film, we designed new simultaneous BOPA lines in 2009, 2013, 2014 with our unique orientation technology. Two lines were available in 2009. Equipped with six lines of cast tenter frame biaxial orientation stretching technology, Cangzhou Donghong Packing Material Co. Ltd. is the TOP ONE BOPA film / Polyamide Film manufacturer in China with total production capability of 30,000MT per year.

We provide excellent base material for film conversion such as printing, metallization, lamination. Our versatile films are ideally suitable for all kinds of packaging applications.

As an ISO 9001 certificated company, our BOPA film complies with RoHS Directive 2002/95/EC and its subsequent amendments, and also complies with FDA 21 CFR 177.1500 (b)(6.2), European Commission Directive 2007/19/EC, and Commission Regulation(EU) No 10/2011.

We have excellent technical engineers team, experienced production control team, and are equipped with automated continuous process, thickness gauge control and online surface defect inspection system.

Characteristics of BOPA film

1. Excellent tensile strength, resistance to impact strength and puncture resistance.

2. Excellent toughness and resistance to pinhole and punctures.

3. Good barrier properties to odors and gases (oxygen, nitrogen, carbon dioxide).

4. Excellent resistance to oil, fats and chemical solvent.

5. BOPA has a wide range of usage temperatures (-60℃ to +150℃). The maximum melting point is + 225℃ and BOPA has stable mechanical properties in low or high operating temperatures.

6. BOPA is highly hygienic, non-toxic, odorless, and tasteless, which is excellent for packaging of products with demanding hygienic requirements.

7. Good transparency, gloss and printing performance, with low haze.

8. BOPA has excellent performance in an environment rich with humidity.

Application of BOPA Film

The excellent features of BOPA film make it widely used both in food and non-food industries, such as electrical, insulation, agriculture, food packaging, and medical devices. Mostly BOPA film is laminated with other materials (PE, EVA, PET, CPP, BOPP, BP, aluminum foil and paper) with the objective of providing a more comprehensive performance.

The laminated structure is then utilized for:

(1) Food packaging: vacuum refrigerated, vacuum retort and modified atmosphere packages (ham, chicken, sausage and other animal proteins), spice, salty food (pickles), vegetables, aquatic foods, tea, coffee and flavorings.

(2) Electrical, insulation and medical: sterile medical devices / medicine, cosmetics, scouring agents, shampoo, integrated circuits and other instruments.

Film.jpg)