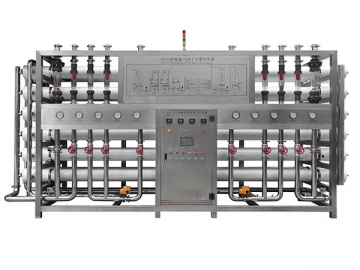

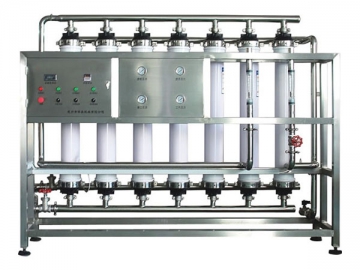

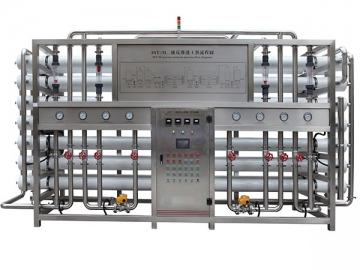

Hollow Fiber Ultrafiltration System

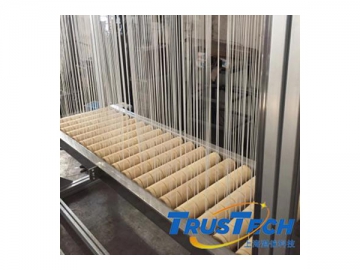

The ultrafiltration process takes place in the membrane model, within the hollow fiber membranes. These membranes function according to a dead-end principle. EcoPura relies on an in/out method of operation: the untreated water flows into the hollow fibers, and the filtered water flows out and across the UF membrane of the hollow fibers. The ultrafiltrate flow remnants are collected in the central pipe inside the membrane then led off. Cleaning of the hollow fiber elements is affected by the back-flushing opposite to the filtration direction of the ultrafiltrate. Individual filter elements are then disabled while the other filters continue to produce ultrafiltrate for both back flushing and continuous ultrafiltrate preparation.

Customized designs and solutions are available based on different raw water sources. We pay strict attention to each tiny process to ensure the final, purified water is both safe and healthy for human consumption.

Water Saving Technology

- Patented concentrated water recycling usage

- Uses technology and design optimization to achieve water conservation

Energy Saving and Consumption Reduction

- Frequency conversion technology

- Technology and design optimization to achieve consumption reduction

Online Monitoring

- Remote human to machine interface monitoring

- Each stage in the working process is monitored online

- Touch screen control and monitoring

Aseptic Piping

- German standard automatic welding technology with no dead angles

Benefits to EcoPura's Ultrafiltration System

1. Large filtration surface: The ultrafiltration with hollow fibers provides a large surface area for filtration processes with only a slight pressure, which leads to a reduced energy consumption.

2. Interruption-free Operation: Due to separate switching of the filter units, the filter modules can be rinsed with the ultrafiltrate. This is supplied directly without an intermediate storage from the filter modules, allowing them to continuously operate.

3. Safe Cleaning: The in/out concept offers optimum conditions for the effective and safe cleaning of the hollow filter membranes.

4. Cleaning with Filtered Media: During the CIP process (cleaning with chemicals), the chemicals are added to untreated water before the ultrafiltration process, allowing them to become highly filtered before they are used.

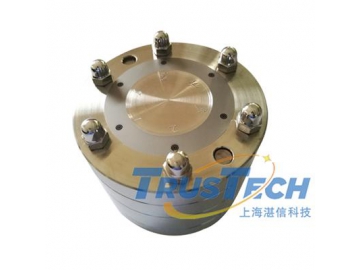

5. Top Quality System Conception: The ultrafiltration system is built using long-lasting specialized steel components, making it a powerful element in your water treatment process.

6. Hygienic Back-Flushing Process: Due to the bypassing structure of the filtration elements, the back-flushing process can be carried out by the ultrafiltrate without the use of a backflush pump and storage tank. If requested, the system can be designed with a hot water sanitation option, permitting safe operation and sanitizing without the use of chemicals in the event of microbial contamination.