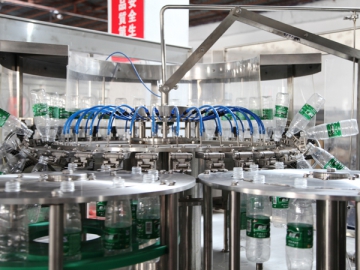

Rinsing, Filling and Capping Monoblock for Water

EcoPura's rinsing, filling, capping 3-in-1 or 4-in-1 monoblock uses a gripping tool to clamp the bottle neck, allowing for full control of bottle transmission, as well as automatic filling and capping via PLC control. There is no need to rinse the bottles, and all electrical components come from internationally known companies. Any area where liquid comes into contact with the bottle is certified to food grade AISI316L or AISI304 standards to help users maximize the output and production time will keeping costs and environmental impact low.

Machine Components

Rinsing system: Rinsing gripper dial, separating water dial, water trough

Filling system: Liquid tank, filling valves, controlling rings

Capping system: Screwing capper, cap sorter, falling cap guide

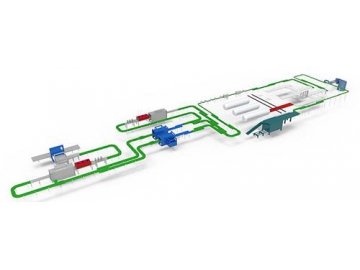

Driven system: gear-driven, main- motor, gear wheel

Feeding system: Guide board, star wheel, conveying chains

Electricity controlling system: Adjustable speed with frequency conversion, PLC, touch-screen operation

Main Configuration

Sliding bearing: Igus Germany.

Frequency inverter: Mitsubishi

PLC & Touch screen: Siemens or Mitsubishi

Pneumatic components: Festo Germany

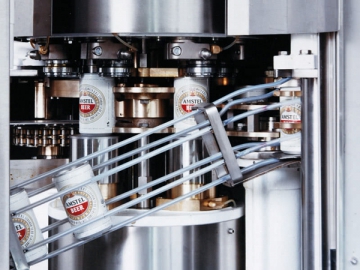

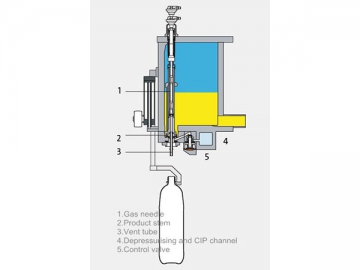

Method of Operation

The filling process begins once the PET container is centered underneath the valve. Two different speeds guarantee an optimum flow, and the amount of liquid flowing into the bottle is monitored by an inductive flow meter. Once the exact filling volume has been reached, the vale closes and the filled bottle then exits the machine.

Characteristics

High micro-biological safety through contact-free filling

Exact fill quantity amount is determined using an inductive flow meter

Perfect flow characteristics due to two possible filling speeds

Turbulence-free switching of speeds using solenoid valve technology

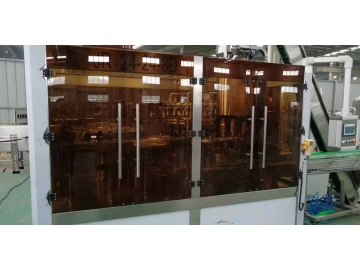

Hygienic design

Closed CIP circuit

Electro-pneumatically controlled filling valve functions

Technical Parameters

Filling Type: Gravity filling

Filling Capacity: 2,000-30,000Bph@500ml

Filling Head: 8-100

Bottle Height: 150-320mm

Bottle Diameter: 40-110mm

Application: Purified water, mineral water, distilled water, non-carbonated beverage