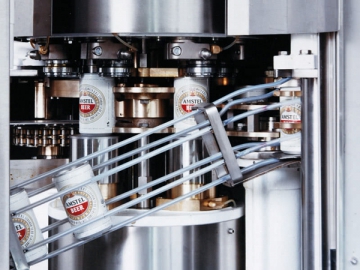

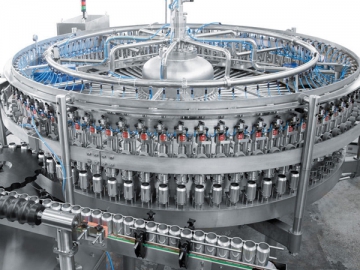

Can Filler

EcoPura's soft drink can filling machine uses an isotonic technology for filling. After passing through the pushing wheel, the empty can will enter a lift can supporting disc and the filling valves are aligned with the empty can. The can is then lifted for sealing, meaning the valves will open automatically after the can is filled. The liquid filled can is then sent to the capping area via a conveyor system, and the caps are placed on the can mouth by a capping feeder and pressing head. When the can supporting mechanism rises, the pressing head presses against the can mouth, and the sealing wheel then carries our pre and final sealing. After the sealing process is complete, cans are pushed out onto the post conveyor system.

Main Configuration

PLC & Touch Screen: Mitsubishi Japan

Frequency Converter & Proximity Switch: SICK Germany

Solenoid Valve: DKC South Korea

For CSD Beverage Filling

Filling Type: Isotonic filling

Filling Capacity: 2,000-24,000Bph@330ml

Filling Head: 12-36

Application: Carbonated beverages such as soda or sparkling water

For Non-Carbonated Beverage Filling

Filling Type: Normal pressure filling

Filling Capacity: 2,000-24,000Bph@330ml

Filling Head: 12-36

Application: Non-carbonated beverage like juice, milk, and tea