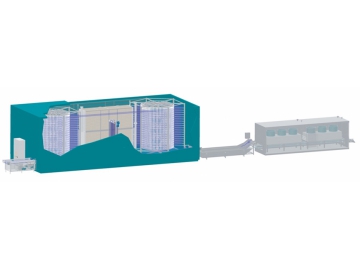

Glazing Line

Wetting Station/Wetting Booth

Ceramic bisque needs be wetted with water after its surface being cleaned with surface dust blown off. This is done to cool down the hot green ware surface and to drive out trapped gases that might bubble up through the glaze causing blisters. The wetting station also can be placed before a printer or sandblaster for spraying glue on the biscuit (or bisque).

Engober

The engober applies engobes on bisque-fired wares. The most suitable size of spray booth and spray nozzle should be chosen depending on the size of ceramic ware and the amount of glaze to be used. The engobing unit is suitable for large size wall and floor tiles, glazed roof tiles, ashlar tiles, and various textured tiles.

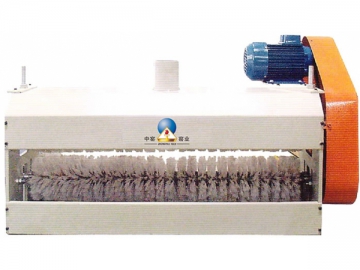

Brushing Unit

The brushing unit brushes dust and burrs off the trimmed bottom and top of green wares entering the glazing line.

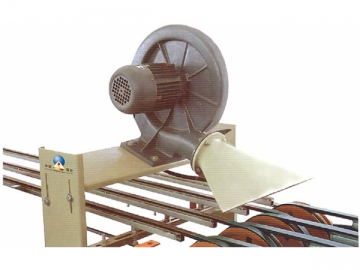

Blower Fan for Dust Removal

The blower fan blows dust and impurities off the surface of ceramic tiles.

Screen Printer with Belt Conveyor

After glazing or sanding, the ceramic ware can be printed with beautiful patterns using a screen printer.

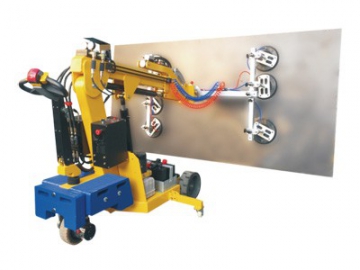

Solid Stream Spray Gun

The glaze spray gun jets out a single solid stream of glazes onto the ceramic ware. The result is a uniform glaze coat. This spray gun accepts a wide range of glaze viscosities, and can rinse the glazed surface after glazing is done. A solid stream spray pattern works better on thin surfaces than a conical spray pattern.