Liquid Silicone Rubber (LSR) for Silicone Plugs

Basic Model:

LIM1520-50A/B

Product Description

LIM1520-50A/B is a two-part liquid insulated silicone rubber for injection molding processes. This silicone rubber is particular developed for the manufacturing of silicone plugs. All LSR are platinum cured materials which are mixed in a 1:1 ratio by weight.

Main Application

The elastomeric material is perfect for making silicone plugs

Usage

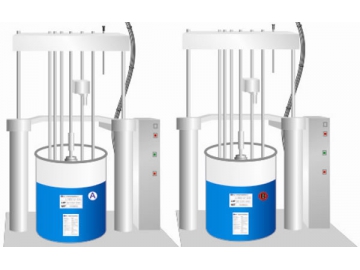

Two parts of the liquid silicone rubber (A and B) are respectively stored in 20kg or 200kg barrels. Before being pumped into the molding chamber, they are precisely weighed by special weighing equipment and uniformly mixed in a static mixer by a ratio of 1:1. After mixed, A/B mixture can be stored for 7 days under 23℃. If the molding machine will stop for a long time, the pumping pipe should be cleaned.

Packaging

20kg/barrel or 200kg/barrel

| Before curing | Physical properties | Test method | Unit | LIM1520-50A/B |

| Appearance (Color) | A: Transparent; B: Red | |||

| Solid content | % | 100 | ||

| Viscosity | DIN53019 | mPa.s | (80-90) x 104 | |

| After curing | SHORE Hardness | D2204 | A | 51 ~ 53 |

| Tensile strength | D412 | MPa | ≥8 | |

| Elongation at Break | D412 | % | ≥500 | |

| Tear strength | D624B | KN/m | > 28 | |

| Volume resistivity | IEC60093 | Ω.cm | 1.0 x 1015 | |

| Resilience | IEC60250 | % | ≥ 60 | |

| Linear shrinkage | JISK 6301 | % | ≤2.2 | |

| Tension set | D412 DIE C | % | ≤ 4.5 |

Notes:

Storage: Store the electrically conductive rubber in an indoor dry and ventilated place at room temperature, and avoid direct sun exposure. It can be stored for 12 month

Viscosity is measured using NDJ-79 rotary viscosimeter

Molding condition: High pressure curing for 10 minutes at 140℃

Post curing condition: Curing for 2 hours at 200℃

Above parameters are only used for reference. They can not be used as a standard. For specific process conditions, you can refer to our product specifications or contact our engineering department.

Shenzhen SQUARE Silicone Co., Ltd.

Address:Building 9th, 3rd Phase, Hemei Industrial Park, Pingzi Road, Pingdi Block, Shenzhen, PR China 518117

Tel.:

(Overseas)

Ext:837

Fax: 86-755-28805428