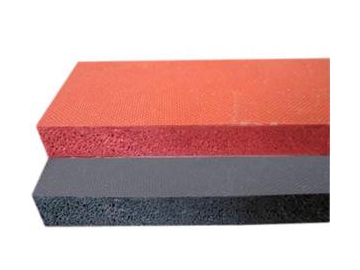

Insulating Silicone Rubber for Laser printer roller

Basic Model:

LSR6900-15A/B, LSR6900-20A/B, LSR6900-27A/B, LSR6900-30A/B, LIM6900-40A/B, LSR6900-50A/B

Product Description

This product is a two-component, platinum-catalyzed liquid silicone rubber, suitable for injection molding process. It is mainly used as elastic material on the insulating pressure roller of OA equipment such as laser printers, copiers, etc.

Key Features

The insulating silicone rubber comes with high elastic resilience, low volatility, high thermal stability and low compression set.

Packaging

20kg/pail or 200kg/pail

| Physical properties | Test method | Unit | LSR6900-15A/B | LSR6900-20A/B | LSR6900-27A/B | LSR6900-30A/B | LSR6900-40A/B |

| Appearance (Color) | Iron Red | Iron Red | Iron Red | Iron Red | Iron Red | ||

| Specific gravity | D792 | 1.220±0.02 | |||||

| Hardness | D2204/DIN5305 | A/Asker C | 3/15 | 5/20 | 12/32 | 10/30 | 20/40 |

| Viscosity | DIN53019 | mPa.s | (5 ~ 10)×104 | (5 ~ 10)×104 | (8 ~ 10)×104 | (5 ~ 10)×104 | (10 ~ 15)×104 |

| Tensile strength | D412 | MPa | ≥0.8 | ≥1.0 | ≥4.0 | ≥1.2 | ≥1.2 |

| Elongation at Break | D412 | % | ≥400 | ≥400 | ≥750 | ≥400 | ≥400 |

| Tear strength | D624B | KN/m | ≥2 | ≥2 | ≥4.5 | ≥2 | ≥2 |

| Linear shrinkage | JISK 6301 | % | ≤2.5 | ≤2.5 | ≤2.3 | ≤2.5 | ≤2.5 |

| Tension set | D412 DIE C | % | ≤2 | ≤2 | ≤4.5 | ≤2 | ≤2 |

| Elastic resilience | % | ≥15 | ≥20 | ≥45 | ≥35 | ≥50 | |

| Compression set | DIN53 517 22hrs @ 175 ℃ | % | ≤10 (200 ℃x4h 180 ℃ x22h, compression 25% ) | ||||

| Curing time (150 ℃) | Tc10≥8s , Tc90≤45s | ||||||

Notes:

1) Store the platinum-cure silicone rubber in an indoor dry and ventilated place at a room temperature, and keep it away from direct sun. Storage time is 12 months.

2) Parameters in the table are only used for reference. For detailed molding conditions, please contact us directly.

Shenzhen SQUARE Silicone Co., Ltd.

Address:Building 9th, 3rd Phase, Hemei Industrial Park, Pingzi Road, Pingdi Block, Shenzhen, PR China 518117

Tel.:

(Overseas)

Ext:837

Fax: 86-755-28805428