Foam Liquid Silicone for Laser Printer

Basic Model:

LIM6934-20A/B, LIM6934-30A/B, LIM6934-40A/B

Product Description

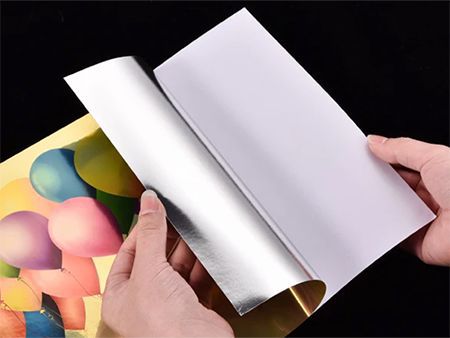

Here you will find an excellent two-component, platinum-cured liquid silicone rubber suitable for injection molding process. The injection silicone can be injected molded to the elastic coating of a pressure roller in office printer and copier. It can be insulating or conductive. Two components (A and B) of the silicone rubber can be mixed by a proper ratio and after mixing, the mixture under a sealing condition can be used for 5 days at 20℃. The time will reduce when temperature rises.

Key Features

The silicone elastomer delivers high elastic resilience, low volatility, high thermal stability and low compression set.

Main Application

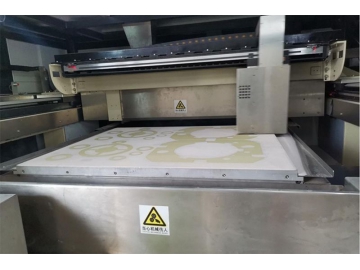

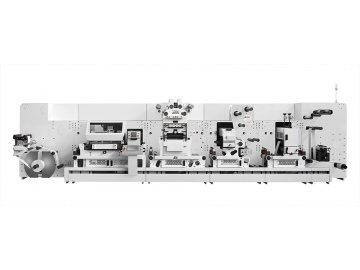

Surface elastic material for the insulating or conductive pressure roller of laser printer and copying machine

Packaging

20kg/pail or 200kg/pail

| Properties | Test method | Unit | LIM6934-20A/B | LIM6934-30A/B | LIM6934-40A/B |

| Appearance | Visual | Red | Red | Red | |

| Hardness | DIN53505 | Asker C | 18~22 | 28~32 | 38~42 |

| Viscosity | DIN53019 | mPa.s | (9~11) x104 | (9~11) x104 | (9~11) x104 |

| Tensile strength | D412 | MPa | ≥0.3 | ≥0.5 | ≥0.7 |

| Tear strength | D624B | KN/m | ≥1 | ≥1 | ≥1 |

| Elongation at break | D412 | % | ≥200 | ≥200 | ≥200 |

| Rebound | % | ≥40 | ≥50 | ≥70 |

Notes:

1) Store the liquid silicone rubber in an indoor dry and ventilated place at a room temperature, and keep it away from direct sun. Storage time is 12 months.

2) Parameters in the table are only used for reference. For detailed molding conditions, please contact us directly.

Shenzhen SQUARE Silicone Co., Ltd.

Address:Building 9th, 3rd Phase, Hemei Industrial Park, Pingzi Road, Pingdi Block, Shenzhen, PR China 518117

Tel.:

(Overseas)

Ext:837

Fax: 86-755-28805428