Ultra Clear Silicone Rubber for Goggles

Models:

LIM3630-30A/B,LIM3630-50A/B

Product Description

This LIM3630 series silicone rubber from SQUARE is an ultra clear, high performance liquid silicone rubber made from a two-component system and catalyzed by platinum. It is suitable for injection molding of diving goggles.

The two-component silicone complies with the standards of USA FDA CFR 21.Part.177.2600, EN14350 for volatile compound and RoHS. After mixed in the prescribed amounts, the two components can be safely operated for 5 days under sealing condition and at 20℃. The rise of temperature will shorten the time.

Features

Extremely high transparency

Excellent elastic resilience

Superb thermal stability and weather resistance (-60℃~250℃)

Anti-yellowing

Anti heat aging

Main Application

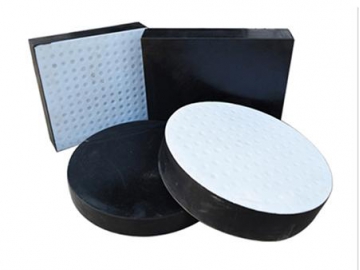

The platinum cure silicone rubber is mainly used to making swimming goggles and other products that show high requirement for transparency.

Packaging

20kg/pail or 200kg/pail

| Physical properties | Test method | Unit | LIM3630-30A/B | LIM3630-50A/B |

| Appearance (color) | Visual test | Transparent | Transparent | |

| Viscosity | DIN53019 | mPa.s | A: (5.0 ~ 6.0)×104 | A: (5.3 ~ 6.0)×104 |

| B: (4.5 ~ 5.5)×104 | B: (3.1 ~ 4.5)×104 | |||

| SHORE Hardness | D2204 | A | 28 ~ 32 | 48 ~ 52 |

| Tensile strength | D412 | MPa | ≥2.5 | > 4.5 |

| Elongation at Break | D412 | % | ≥150 | > 300 |

| Tear strength | D624B | KN/m | ≥7.0 | ≥12 |

| Resilience | % | ≥65 | > 44 | |

| Tension set | D412 DIE C | % | ≤3.0 | < 2 |

Notes:

1) Store the silicone rubber at room temperature in an indoor dry and ventilated place and keep it out of direct sunlight. Shelf life is 12 months.

2) Typical properties shown in the table are only for reference use. For specific molding process, please contact us directly.

Shenzhen SQUARE Silicone Co., Ltd.

Address:Building 9th, 3rd Phase, Hemei Industrial Park, Pingzi Road, Pingdi Block, Shenzhen, PR China 518117

Tel.:

(Overseas)

Ext:837

Fax: 86-755-28805428