Belt Conveyor

Applications of the belt conveyor abound, as it is frequently seen in various manufacturing sectors, including home appliances, electronics, machinery, tobacco, injection molding, printing, and food. The belt conveyor is typically placed at the start of any material process for transfer of products waiting to be processed, assembled, inspected, packed, and shipped.

Whether it is an intermittent, continuous or variable-speed conveying process you had wished for, here at Changrong you can find the right belt conveyor in straight-line, inclined, or around-the-corner designs that best fit in your factory layout.

Depending on the workload, customers can choose either a light duty conveyor belt for handling electronic plastics, food, chemicals and pharmaceuticals, or a heavy-duty rubber belt for use in mineral processing.

Known for its ability to carry items, powders and granules over long distance, the belt conveying equipment is very easy to maintain, incorporate into a computerized or automated process. Anything weighing less than 100kg can be moved with a belt conveyor at fast speed, steadily and with little noise.

Below is a short description outlining several types of belt conveyor:

DT is a stationary belt conveyor commonly seen in metallurgy, mining, coal, seaport, power station, building material, chemical engineering, and petroleum industries. A complete stationary conveying system is comprised of several standard-alone units that convey individual items and loose materials over a long, fixed path.

| Belt Width (mm) | 500 | 650 | 800 | 1000 | 1200 | 1400 |

| Belt Speed (m/s) | 0.8-2.5 | 0.8-2.5 | 0.8-2.5 | 0.8-2.5 | 0.8-2.5 | 0.8-2.5 |

| Conveying Capacity (m3/h) | 69-217 | 127-397 | 198-781 | 324-1622 | 593-2674 | 825-3718 |

| Conveyor Inclination | 0-220 | 0-220 | 0-220 | 0-220 | 0-220 | 0-220 |

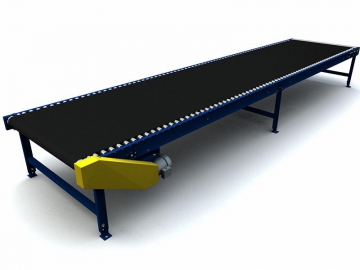

Pictured below is one of our small-sized conveyors.

Both the flat belt conveyor and the troughed belt conveyor are suitable for conveying lightweight bulk loads within a factory. The flat belt conveyor is mainly used to transfer lumpy materials in food and electronics industries as part of a streamline process.

Shown here is a mobile belt conveyor that runs on caster wheels.

This type of conveyor can adapt to various conveying applications and is easy to move around. It conveys material at an angle that can be adjusted for moving various bulk materials and unit loads. Multiple conveyors can work together to handle demanding material transfer applications.

For steep angle conveying of loose materials, the corrugated sidewall belt conveyor is the right way to go.

Utilizing corrugated sideways and cross cleats to prevent spillage, the conveyor excels at material conveying at angles greater than 50 degrees. It is also built to transfer material to greater heights than is possible with conventional belt conveyors.