Layer Cage / Battery Cage

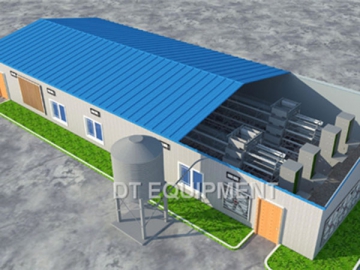

The A-frame or H-frame layer cage or battery cage system is manufactured by Dingtuo, a professional poultry equipment manufacturer from China, for safe and efficient egg production. The followed specification is A-frame cage system, for H-frame cage system please contact us.

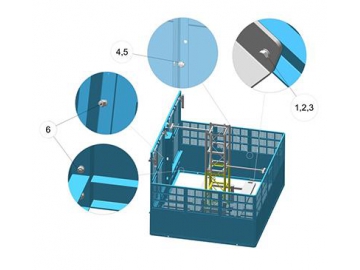

A-Frame Laying Cage System Advantages:

1. Compared with stacked cage system, it ensures lower cost of investment.

2. It is specially designed to provide more raising area and thereby improve egg production efficiency.

3. The A-frame layer cage is easy to maintain and repair. The cage system can be controlled according to suggestive steps.

4. Automatic egg conveying system is able to enhance the rate of clean eggs.

5. The whole poultry system is designed for easy sterilization, ensuring ease of controlling the spread of parasitic disease and worm disease.

6. Automatic water feeding system offers uniform water pressure and ensures that each laying chicken can drink enough water.

7. Lengthened feed trough comes with an excellently designed edge which reduces waste of feed and increase feed conversion ratio.

8. Well ventilation makes sure that chickens in the layer cage system will not suffocate due to high temperature.

9. The battery cage system is provided with an Italian manure belt which keeps the system clean, reduces bacteria growth and lowers disease and death rate of laying hens.

Technical Parameters

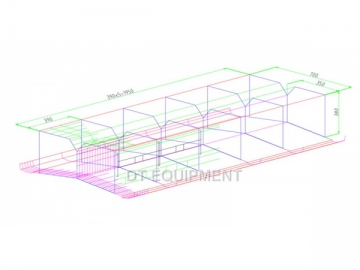

1. A-Frame 3-Layer Cage System

Overall dimensions: 2000(L)x1900(W)x1620(H) mm

Single cage size: 390(L)x350(W)x380(H) mm

Cage quantity: 5 at each side, 10 in total

Raising capacity: 120 hens/group

2. A-Frame 4-Layer Cage System

Overall dimensions: 2000(L)x2200(W)x2020(H) mm

Single cage size: 390(L)x350(W)x380(H) mm

Cage quantity: 5 at each side, 10 in total

Raising capacity: 160 hens/group

3. A-Frame 3-Row 4-Layer Cage System

Single set size (WxH): 2.61mx2.49m

Raising capacity: 160 hens/group

Use:

It is an excellent choice for cage rearing of laying hens.

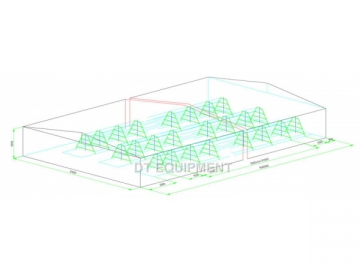

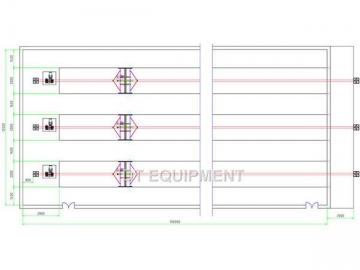

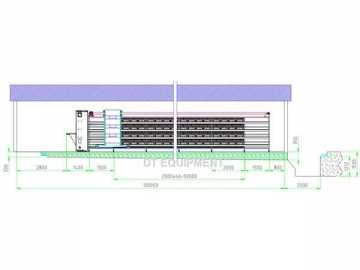

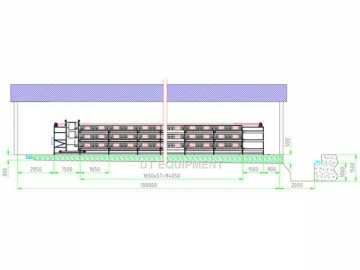

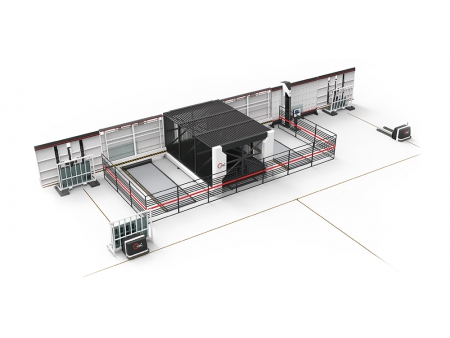

Design Sketch

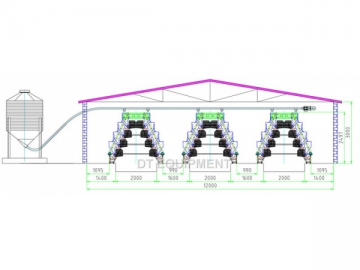

1. Battery Cage with Accesses from Both Sides

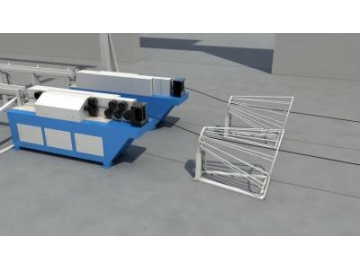

2. Feeding System

Feed tower, auto feeding machine for uniform feed supply;

Distance between two rows: 0.99m (Space for at least one person operation)

Height of 4-tier cage: 2.497m

Manure pit width: 2m

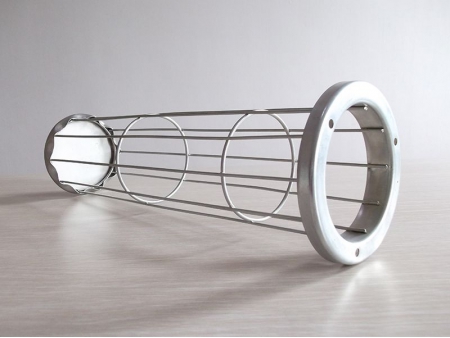

3. Automatic Egg Collection System and Automatic Manure Removal System

Length of egg collector and feeding machine stand: 1.4 1.5 1.5=4.4m

Manure pit depth: 0.3-0.5m (Back section is deeper than front section)

Size of manure pit outside the hen house (Width x Depth): 2x1.5m