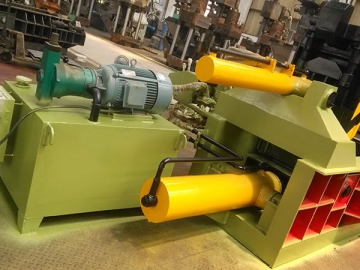

Scrap Metal Baler

Advantages:

1. Quick transport, installation

2. Convenient operation

3. Stable structure, sealed tightly

4. Customized bale size, suitable for kinds of transportations

5. Saves space and cost, improve working efficiency.

Characteristics of scrap metal baler:

1. Hydraulic system features high power, stability, safety and reliability

2. Optional operations: manual or auto, cycle time: 90S

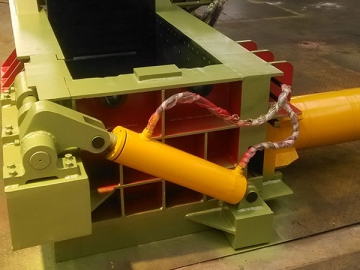

3. Four discharge ways: side-out, side turn out, front push out, front turn out.

4. Quick installation, for small types, no need for fixing screws.

5. Optional power supply, electrical or diesel power.

6. Optional models for different situations, power range from 63Tons to 600Tons.

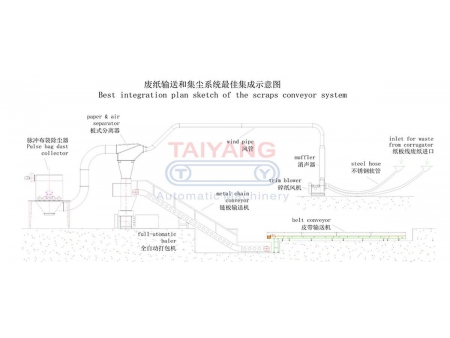

Working principles or process:

Put the metal scraps into the chamber in the hydraulic baler machine manually or mechanically---hydraulic cylinder press forms the regular scraps foundry returns--- discharge --- ready for returning to the furnace

Applications:

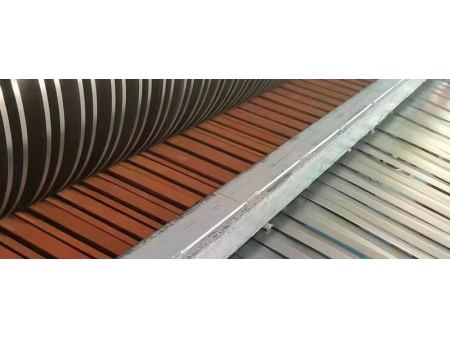

These scrap metal balers are used for cold pressing and recycling many different types of metal scrap, including steel shavings, scrap steel, iron, scrap copper and aluminum. The hydraulic baler squeezes the scraps into a regular square or cylindrical shape that is easier to store and transport for processing.