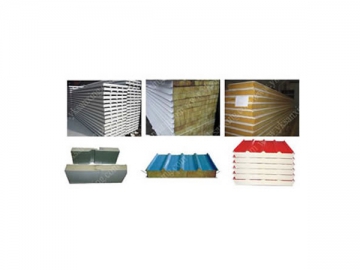

Rockwool Sandwich Panel Machine

The rockwool sandwich panel machine contains roll forming equipment and a sandwich panel laminating system that can work independently of each other. It produces corrugated sandwich panels directly as well as simple corrugated sheets. The annual production of our rockwool sandwich panel machine is 500,000 square meters. The roll forming machine features feeding, roll forming and cutting system, while the laminating system features the decoiler, feeding, squeezing, heating, laminating, edge rolling, edge turnover, groove making, edge pruning pneumatic device, automatic cutting, and a PLC system.

This sandwich panel machine operates with a PLC system to set options such as the panel length and then cuts it automatically. It has a stylish appearance as well as low noise and high efficiency. This machine is designed based on advanced production techniques and combines the advantages of both mechanical and electrical equipment. It is used to create sheets that will be used in roofs and walls of factories, garages, storage areas, exhibition centers and more.

Main Technical Specifications of the Rock Wool Sandwich Panel Machine

Size: 38000 mm × 3600 mm × 3300 mm

Total weight: about 24000 kg

Controlling system: PLC

Total power including heating: about 40 kW

Working speed: 1000~3000 mm/min

Density of EPS: >18 kg/mm

Suitable material for production: 1000 mm ~ 1200 mm × (0.5~0.6 mm)