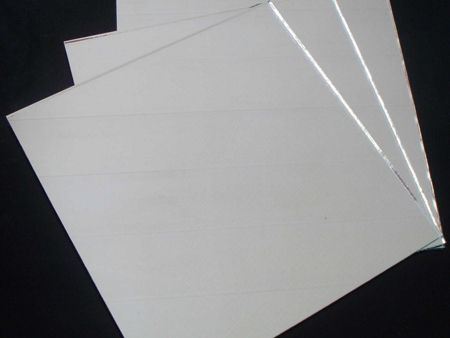

Aluminum Mirror

Color: clear, ultra clear, bronze, grey, pink, golden bronze, black

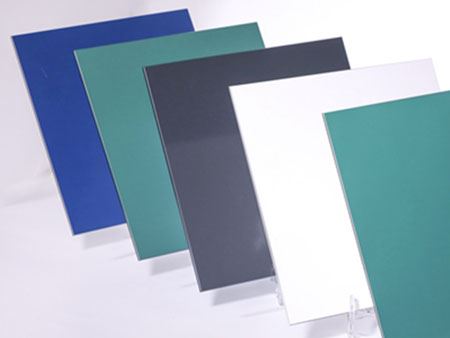

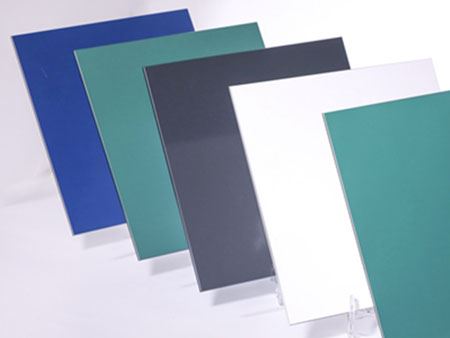

Back Color: grey, green, blue, white, yellow, custom color acceptable

Thickness: 3 mm, 3.5 mm, 4 mm, 4.5 mm, 5 mm, 5.5 mm, 6 mm, 8 mm, 10 mm

Size: 1220*914 mm, 1830*1220 mm, 2000*1600 mm, 2200*1600 mm, 2200*1650 mm, 2250*1650 mm, 2440*1830 mm, 3300*1830 mm, 3300*2140 mm, 3300*2250 mm, 3300*2440 mm, 3660*2140 mm, 3660*2440 mm, custom size acceptable

Standard: GB/T32025 (China)

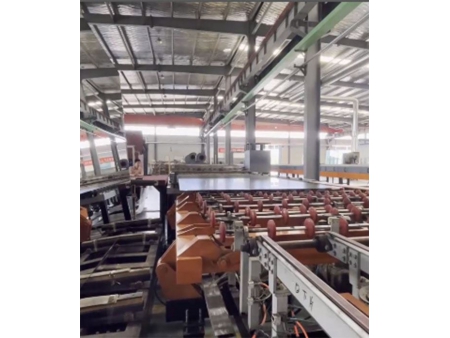

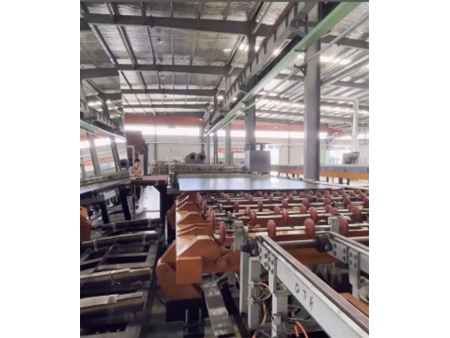

Aluminum mirror is a superior quality mirror that is manufactured using high-quality float glass. The production process involves several steps to ensure that the final product is of the highest standard. Firstly, the raw material undergoes a thorough cleaning process with pure water. It is then polished and dried before entering the coating room, where magnetron sputtering deposition is deployed onto the glass surface, creating a dense and stable reflective aluminum coating through an oxidation reaction. To protect the aluminum coating, a corrosion-resistant lacquer and a waterproof lacquer are applied. This forms a protective layer that completely dries during the production line process. The result is a flawless aluminum mirror that has no aluminum spots, black spots, paint spots or any other defects.

The technology used in producing magnetron sputtering aluminum mirrors combines the principles of sputtering coating technology from advanced low-E glass production lines and the lacquer spraying and drying technology from silver mirror production lines. This innovative method overcomes quality defects often present in traditional aluminum mirror production processes.

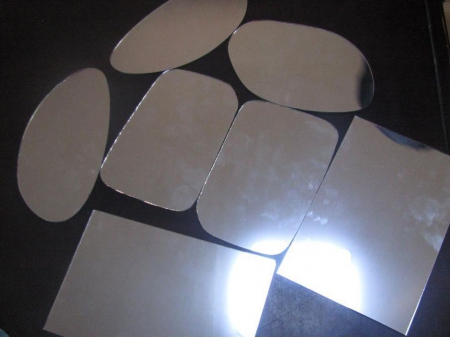

Aluminum mirrors can be made by various flat glass substrates to adapt to the needs of different markets. For instance, ultra-clear float glass can be used to meet high-end market requirements, while tinted glasses can create colorful mirrors for decorative purposes. Tempered glass is also an option to satisfy the needs of the price-sensitive market.

- High reflectivity

- Highly resistant to corrosion protected by Italian FENZI paint

- Easily processed by cutting, edging, drilling and etc.

- Suitable for making decorative mirrors and LED mirrors

- Interior decoration and room design

- Furniture, especially that vinyl back safety mirror has been widely used

- Decorative mirrors and LED mirrors