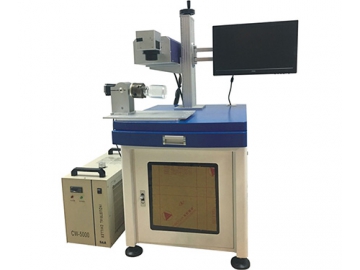

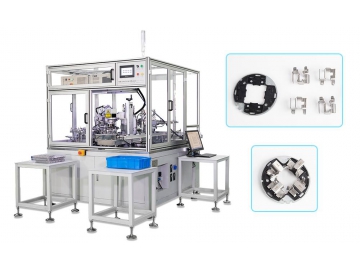

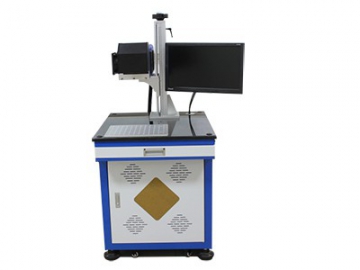

20W Automated Assembly Line Fiber Laser Marking Machine, MF20-B-A Laser Marking System

Applicable Materials

The MF20-B-A laser marking system is applicable for surface marking on various alloy materials, such as plastics, stainless steel, aluminum oxide, cast iron, wooden products, copper and so on. Application examples include marking on drink containers, cigarette packages, aluminum profile marking, hair care product packaging and perfume packaging.

| Model | Laser power (W) | Marking area (mm) | Working distance (mm) | Minimum line width (mm) | Minimum character (mm) | Supply voltage | Dimension (mm) | Weight (Kg) | Working environment | Total power (kW) |

| MF20-B-A | 20 | 70X70 110x110 175X175 | 120 188 280 | 0.05 | 0.5 | AC220V±10%, 50/60Hz | 450 X 210 X 380 (Power box) 730 X 450 X 1350 (Lifter) | 40 | Temp: 5~ 35°C, Humidity:5~85%. No condensate water, no dust or less dust. | 0.8 |

Laser Processing Examples:

Bar code laser marking

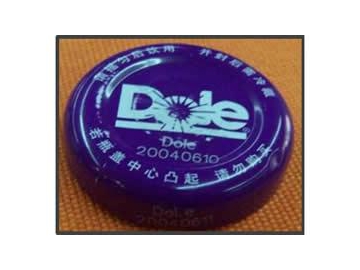

Bar code laser marking Bottle cap laser marking

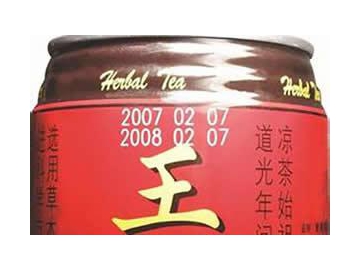

Bottle cap laser marking Can laser marking

Can laser marking Plastic bottle laser marking

Plastic bottle laser marking

Product Feature

1. The highly integrated fiber laser system has high-quality light spot, a laser power with uniform density and a stable laser output power. Even when processing on high-contrast materials like aluminum, gold, or silver, there will be no shadows or virtual open phenomenon.

2. A high-speed digital scanning galvanometer features a small volume, high speed and excellent stability.

3. The modular design, split fiber power box and lifting platform are designed to ensure flexibility of the equipment in order to satisfy complex placement requirements.

4. Usage of an embedded operation system allows for an optimal touch operation interface that supports different fonts, bar codes, and QR codes. This ensures the equipment meets most application technique requirements on the market today.