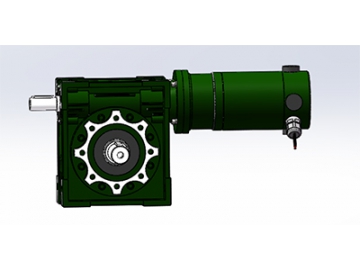

Permanent Magnet Motor Driven Air Compressor

Being a latest model of screw compressor featuring excellent quality and energy efficiency, our permanent magnet motor driven air compressor has integrated the most sophisticated technology of energy efficient and most essential factors.

As very few countries and regions can master such an advanced technology currently in the world, our motor driven compressor represents the high-end trend of the future development in the field of air compressor. Our motor driven air compressor’s design philosophy and techniques have achieved break through from the concept of traditional technology.

Features of Motor driven air compressor

1. Energy Efficiency and Variable Frequency Control

The traditional method of compressor’s speed control is to adjust the inlet valve to regulate the volume of air supply. However, it has high input power and consumes a large amount of energy in the process of valve’s closure. Nevertheless, our variable frequency control of motor driven air compressor can reduce the rotation speed to decrease the air supply to the required volume.

Additionally, having the design of low temperature rise, our motor driven compressor has significantly extended lifespan. We adopt the axial fan motor to force the permanent magnet rotary screw compressor’s ventilation and air cooling, which is fully applicable to working conditions with variable frequency.

2. Energy Saving and Power Factor Compensation

The traditional equipment generally has very low service efficiency and severe waste of energy. The reactive power not only leads to the line loss, but also makes the equipment to have high temperature. However, the worse result is that the active power will decrease due to the reduction of the power factor, leaving a large amount of reactive power consumed in the circuit.

Differently, our motor driven compressor has frequency adjustment device. Thanks to the function of its internal filter capacitor, the consumption of the reactive power is reduced and the active power increased.

3. Energy Saving and Soft Start

Having frequency conversion and energy-saving devices, this selection of screw air compressor can use the soft start and enable the starting current to start from zero. Also, the maximum will not exceed the rated current. It not only reduces the impact to the circuit and the requirement to the power supply capacity, but also guarantees the stable operation of the motor driven air compressor and the lifespan extension of the equipment and valves. Correspondingly, the maintenance cost of the equipment has been largely saved.

Moreover, having quick response time, our motor driven compressor’s motor can enable the volume of air supply to have wide range of adjustment and realize the true constant air pressure. Equipped with a high precision sensor, the permanent magnet motor compressor’s motor can make timely feedback of its rotor position to the compressor controller. Then the controller of our motor driven air compressor can adjust the rotation speed to achieve the most accurate results.