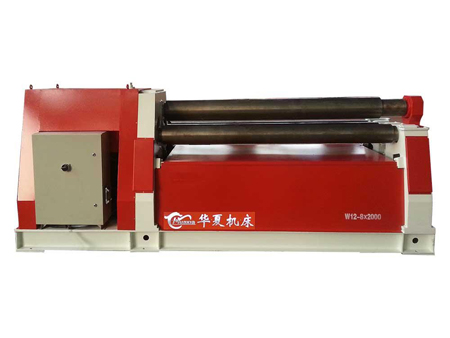

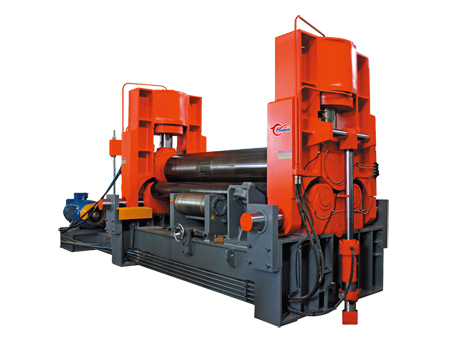

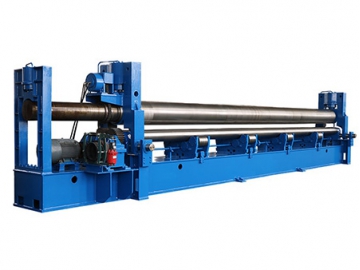

4 Rolls Plate Bending Machine

Request a Quote

The 4 rolls plate bending machine is equipped with an NC system, which improves the degree of automation. The bending machine is commonly used in petroleum, chemical industry, boilers, shipbuilding, metal structure and machinery manufacturing industry.

Parameters| Model | W12-8×2500 | W12-12×2000 | W12-25×3000 | W12-40×2500 |

| Max. thickness of plate mm | 8 | 12 | 25 | 40 |

| Max. width of plate mm | 2500 | 2000 | 3000 | 2500 |

| rolling speed m/min | 6.1 | 4 | 5 | 4 |

| Thickness of pre-bending mm | 6 | 10 | 22 | 36 |

| Min. dia. of plate in full load mm | 750 | 850 | 1150 | 1300 |

| Dia. of upper roller mm | 300 | 380 | 480 | 560 |

| Dia. Of lower roller mm | 280 | 340 | 460 | 520 |

| Dia. Of side roller mm | 230 | 280 | 380 | 420 |

| Main power kW | 15 | 30 | 55 | 60 |

| Dimension(L)mm | 6100 | 7600 | 9000 | 8700 |

| Dimension(W)mm | 2000 | 2000 | 3200 | 3500 |

| Dimension(H)mm | 2070 | 2150 | 2500 | 2900 |

- The bending machine has 4 rolls. The upper roll uses a mechanical transmission, while the bottom and side rolls use lift hydraulic driving. The system features an electric centralized operation system.

- The bending machine is designed with a pre-bending function, both end of metal plate can be pre-bended, and cylindrical workpiece, arc workpiece and tapered workpiece with a certain tapering range can also be rolled on this plate rolling machine through one time feeding process. Metal plate ends can be pre-bended with a minimized residual rectangularity, featuring high work efficiency. Besides, the plate bender has ability for rough leveling on metal plate.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos