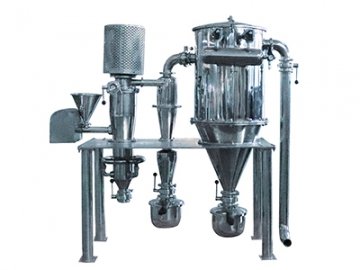

Ultra-Fine Grinding Mill

Description:

Model CWFJ series super fine grinder unit is researched and developed in accordance with our national situations through adopting and digesting the updated advantages of Xi Chuan Co. Ltd. (Japan). This machine possesses the following advantages: stable technical performance, low noises, economic consumption of electricity, high efficiency, beautiful appearance, small occupied area, broad scope of application and etc.. It can treat the material such as chemicals, foodstuff, medicines, cosmetics, dyestuff, resin, shell materials, and etc.. To be compared with the similar domestic products, the finished products’ temperature is low, and the products’ size is even. The size can reach micrometer grade or even sub—micrometer grade, thus it provide better guarantee for the users to develop quality products.

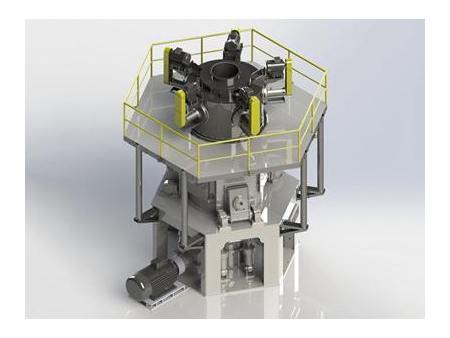

Structure:

This grinder consists of machine support, stepless speed—regulating motor, main motor, feed hopper, crushing chamber. In the crushing chamber there equipped with main working components such as grading device, teeth ring, crushing cutter and etc.. The grading shaft is inside the hollow jacket of the main crushing shaft. The bearings adopt labyrinth seal.

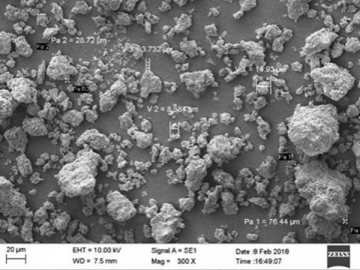

Work Principle:

The material to be crushed is piled up in the hopper, pushed into the crushing chamber by the screw feeder (with variable speed adjustment). Because of the negative pressure action, the material entering the crushing chamber are sheared and impacted high speedily. Simultaneously, the material is vibrated by full air stream. The crushed powder materials are acted by the air stream, and then enter the grading wheel. Because of the rotation of the grading wheel, the powder materials simultaneously are acted by the air motive forces and the centrifugal force. When the air motive force is smaller than the centrifugal force, and the powder material’s size is bigger than the grading size, thus they are thrown into the conical jacket, and then return into the crushing chamber to be kept on being crushed. Under the action of the air motive force, the passed material enters the material—collecting pipeline to get to the auxiliary machine to be exhausted.

Scope of Application:

Minerals: kaolinite, mica, graphite, barite, quartz, zircon sand, calcium carbonate, talc and so on.

Chemical industry: three, three and two antimony molybdenum sulfide oxidation, titanium dioxide, alumina, dyes, pigments, such as carbon black.

Electronics: barium titanate, chromium oxide etc.;

Medicine: bismuth nitrate, cortisone, penicillin, pollen, pearl powder, nimodipine etc.;

Pesticide: carbendazim, thiophanate methyl, weeding, insecticidal powder powder and wettable powder.

Metallurgical: fire retardant materials, high-grade grinding media, ceramics and etc.