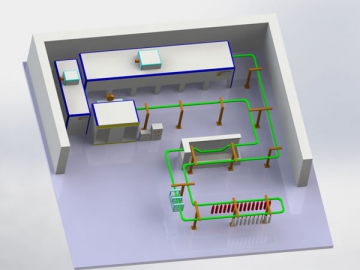

Electrostatic Powder Coating Production Line

The electrostatic powder coating production line is an automatic line for plating powder coatings by means of electrostatic field effect. It mainly consists of powder spray booth, curing oven and conveying appliance.

Equipment

1.Powder spray booth

a. Working principle

While spraying, the electrostatic power field is sensed and generated between the work piece and the spray gun. The powder particles on the nozzle are forced to be charged by the internal electric field of spray gun. Through the atomizing air of the nozzle and electrostatic repulsion atomization, the powder particles are well atomized. The powder particles with negative charge will be absorbed towards the surface of the work piece by the power field. They will surround the positive and negative surfaces of the work piece to achieve excellent coating.

b. Equipment components

This powder spray booth is composed of cabinet, powder spray gun, powder supply device, small cyclone system and first level of filter recovery device, pulse control device, air absorbing device, electric control part, etc.

c. Main structure

The cabinet is made of steel plate and square tube. The filtration system uses the filter element made of imported long fiber material that features excellent durability, shrinkage, elasticity, etc. The recovery system is equipped with first grade of device in gentle recovery ratio.

Among the sprayed powder, the excessive part is taken back by the small cyclone system and filter element in the cycle with the help of fan except what adheres to the work piece. Through the recoil force of the electromagnetic pulse valve, the excessive powder is conveyed to the recycling cabinet for reuse and the recovery rate is about 95%. The spray gun has the characteristics of reasonable structure, convenient operation, even powder output without high voltage discharging, etc.

2. Powder curing oven

It is used for drying the powder on the surface of the work piece and structured with bridge drying tunnel to supply, absorb air at the bottom.

a. Working principle

During drying, the circulating air goes out of the centrifugal fan first. Via the backwind tube, it enters the air heating furnace where it does indirect heat exchange with the hot air generated from the burning gas. The heated air gets into the blast pipe at the indoor lower part and then enters the drying cabinet through the blast air outlet. This oven will dry the work piece with hot air convection from the bottom to the upper. The air after heat exchange goes into the backwind tube from the return air inlet at the bottom to start the next cycle. The cycle pipeline is opened with waste air exhaust vent and the inlet of supplementary fresh air.

b. Equipment components

This powder curing oven comprises of cabinet, circulating fan system, heating system, indoor and outdoor air pipes, smoke exhaust and air curtain system, waste gas processing system and other parts. Therein, the cabinet is assembled with wall plate, top board, frame, door opening system for work piece, etc.

3. Conveying appliance

This device usually adopts the hanging chain or electric hoist for conveying.

Related Names

Powder Coating Machine Manufacturer | Workpiece Powder Coating | Metal Surface Coating System