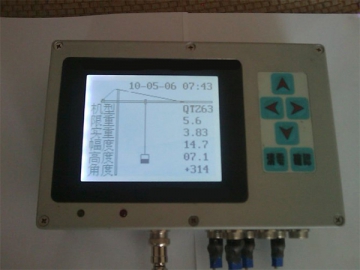

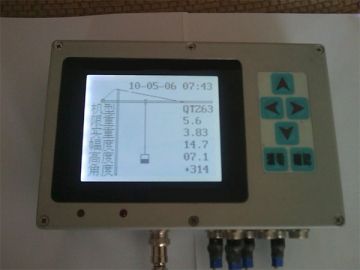

Black Box (for Tower Crane)

The WKS 16A black box for tower cranes is made up of a control center with a keyboard, display screen and microprocessor and multiple sensors for monitoring trolleying, slewing, wind speed, and lifting height. Data can be transmitted between the main board and extension at a distance up to 3,000m. This safety system for tower crane monitors and prevents accidents in real time that may be caused by operator errors.

Main Functions of the Tower Crane Black Box

1) Data recording. The safety monitor records the working parameters of the tower crane, including loading, temperature, wind speed, alarm records and hoisting moment. Pulse signals calculate height, radius and trolleying angle (can increase slewing) and can save up to 5,000 records. Data is transferred to the Flash system in case the power fails or the tower crane capsizes.

2) Safety protection. With several parameters in place for limiting the construction equipment's unsafe movements, you can be confident when you use your hoist. This limits the hoisting moment, hoisting weight, lifting height, radius and slewing angle. When the tower crane overloads, the black box will signal the controls so it moves in a safe direction.

3) Realtime display function. The display instantly shows loading, radius, hoisting moment, wind speed, lifting, and trolleying.

Black Box Parameters

Load moment: 200-4000 KN.m

Load: 4000 KN.m

Max. hoisting height: 520m; Max. radius: 130m

Work temperature: -40 to 85 degrees

Comprehensive precision error: ≤3%

Length of time with no failure: ≥ 3 years