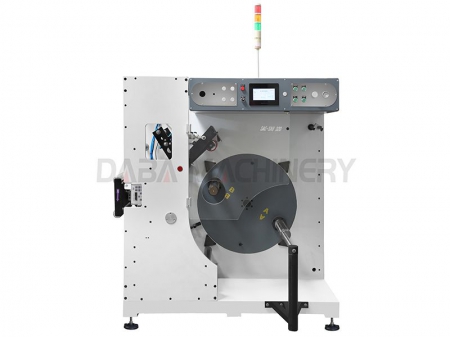

Non-Stop Automatic Turret Rewinder, SAC-350

Request a Quote

Label rewinder

Daba Machinery makes non-stop automatic turret rewinder that ensures continuous rewinding of materials for printing and processing. The turret rewinder automatically cuts the trailing end of the roll and attaches the leading edge to a prepared core, enabling uninterrupted production in label manufacturing. The turret rewinder is equipped with an unique round blade at the upper and lower ends that ensures smooth cutting of various materials.

Applicable Materials

All rolls including plastic films, paper, aluminum foils, adhesive labels etc.

Applications

For continuous rewinding of material rolls from printers and processing equipment.

Specifications

| Model | SAC-350A/B |

| Maximum Rewinding Diameter | 650mm |

| Minimum Rewinding Diameter | 350mm |

| Maximum Speed | 180m/min |

| Material Splicing Time | 15s |

| Material Splicing Method | Fully automatic splicing at pre-set speed |

| Material Splicing Angle | Horizontal |

| Edge Positioning Control | Integrated EPC |

| Material Unloading Method | Manual |

| Paper Core Alignment | Laser positioning |

| Dimensions (L*W*H) | 1550mm*1000mm*1650mm |

| Weight | 1200kg |

| Power | 3kw |

| Voltage | 380V, 50Hz, three-phase |

Features

- Flexible design that can meet almost all demands from customers.

- Simple procedures eliminate the need for specialized training.

- The rewinder is equipped with a stable tension control system using piecewise tension coupling.

- 100% material splicing rate

- Three adjustable settings for automatic unwinder: manual, roll diameter adjustment, and length adjustment.

- Automatic unwinding with EPC function (web guiding system for edge positioning control). Sensors monitor the position of the running roll, and the automatic side guide moves to ensure alignment during splicing.

- Laser positioning for edge alignment.

- Fully automatic side guide for both opaque and transparent rolls.

- Reliable roll slitting and rewinding devices including precision cutting wheels and anvils ensure clean cutting.

- Automatic material splicing at pre-set speed

- Manual unloading part at any time. When cutting materials or connecting a new roll, the previous product needs to be unloaded.

Details

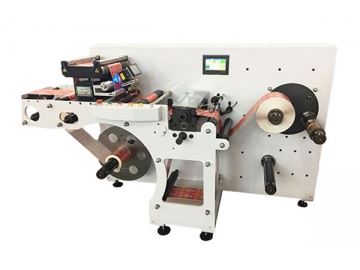

- Touch Screen

Simple and user-friendly interface.

Operatable without specialized training. - Slitting Unit

Equipped with roll cutting and splicing device that is reliable and easy-to-control, facilitating clean cutting and tight splicing. - Material Rack with Floating Roller

Our unique tension coupling technology ensures accurate tensioning when entering the roll. - Guiding Rail with EPC

Automatic unwinding with EPC function (web guiding system for edge positioning control). Sensors monitor the position of the running roll, and the automatic side guide moves to ensure alignment during splicing.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos