删除

Hydraulic Lift

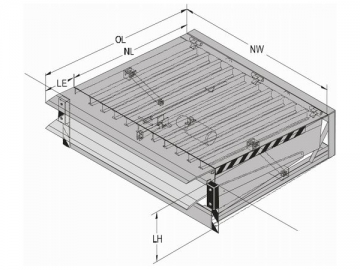

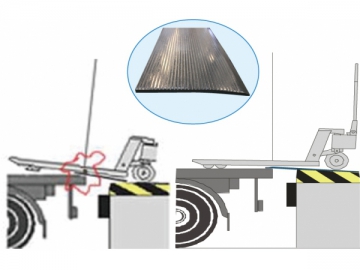

The SINO-DHLhydraulic lift with double cylinder is generally used for cargo loading andunloading. In case there is height difference between the truck and the floor,our product can regulate the height difference by building a follow-up slope,whose height is adjustable based on the loading conditions of the truck.

This material handling equipment

1. Easy Operation

Operation on the control button is required to have the platform rise to thehighest point. The lapping board will land on the truck for goods loading,subsequently. The hydraulic lift will return to the normal position upon thecompletion of task through one-button operation.

2. Multiple Safety Function

This range of isquite safe during operation. In case the truck slides suddenly, the pressuresensor will detect the sudden change to inform the emergency stop valve to stopthe platform movement. The double cylinder can afford the weight of theforklift and the cargo, to avoid accident occurrence.

In addition, the iron stopper for the hydraulic lift is optional to avoid trucksliding. The guard plate can effectively prevent the toe from pinching.Besides, the forklift and the cargo can be well protected, also.

3. Arc Platform

The arc platform makes sure stable height adjustment. Conforming to

4. Double Cylinder

There are two cylinders designed at the left and rightside of the hydraulic lift, ensuring optimal stability and balance duringoperation. In addition to the wide adjustment range, the cylinder is providedin inverted design, eliminating the invalidation of the urgent hydraulic valvecaused by blocking.

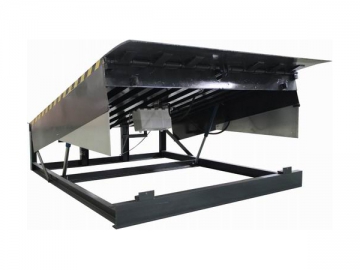

5. Steel Plates with Lath and Lentil Form

The platform surface, front lapping board and theframework are all made of high strength anti-slide corrugated steel plates with lath and lentil form.

6. Fully Enclosed Main Frame

To obtain optimal sturdinessduring transportation, installation and utilization, the main frame of the

7. I Beam

As mentioned above, our hydraulic lift is engineeredwith double cylinders; therefore, it is possible to distribute the 10 I beams(width>1950) uniformly, ensuring the equal distribution of the stress fromthe platform. Our product has longer service life, compared with the devicewith L or △type stiffener, or 6 I beams.

8. Unique Follow-up Design

With the employment of the follow-up design, theautomatic lifter

9. Hydraulic System Imported from

Our product employs the hydraulic system imported from

10. Emergency Braking Device

Under thecircumstance that the truck departs from the lift platform (abnormal workingstate), and the forklift and cargo are on the platform, the braking valve builtin the hydraulic cylinder will brake emergently when detecting the suddengravity variation. To guarantee the safety of the operator, cargo and thetruck, the hydraulic lift will lock automatically after descending for

Note: for the utilization lower than horizontal plane, the security supportmakes no difference.

11. Emergency Stopping Push Button

Our hydraulic lift can be stopped by pressing the emergency stopping pushbutton on the control box for abnormal situation.

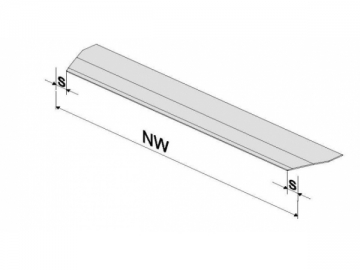

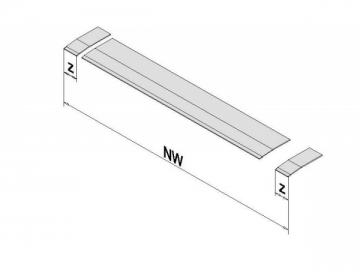

12. Unique Duckbilled Thickened LappingBoard

The lapping board is designed with

The tube welded loose-leaf structure increases the contact area, guaranteeinguniform stress distribution and reasonable force transmission. So, ourhydraulic lift is more sturdy and durable for use.

13.Other Related Information

Rated Bearing Capacity: Dynamic load: 6 tons

Static load

Power Supply: 380V±10%, 50Hz, 0.75kW

Standard Color: RAL5007 Blue

Standard Height: 600

Configurations:

1. A pair of large-scale high quality bumper in the size of 100×W250×500, or

reinforced fibre.

2. An U-shape jackstay for easy maintenance.

3. Lapping board is optional

Trapezoid lapping board

Sectional lapping board