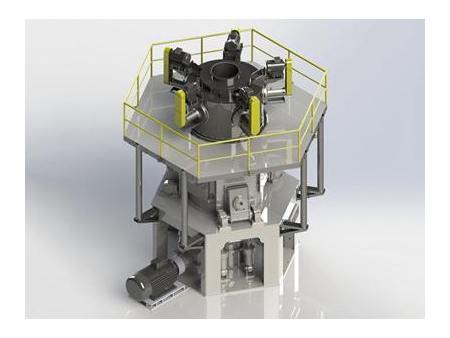

Centrifugal Air Compressor

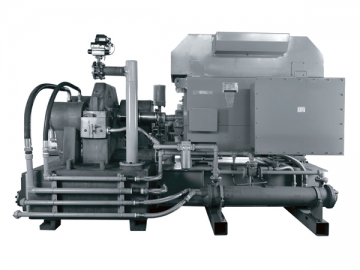

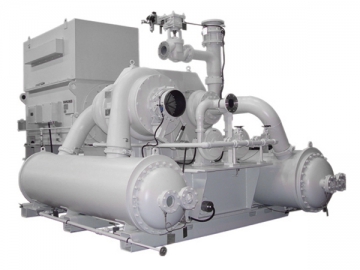

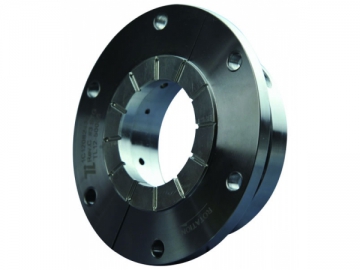

We adopt the most advanced kinetic analysis to our centrifugal air compressor. We analyze the angle and position of each blade on the impeller to find the value of angle, which can ensure the minimum power consumption, the highest efficiency and the effective energy conservation. The centrifugal compressor’s drive system and the electromotor are directly connected by the precision and balanced flexible disc coupling, which can lower the vibration to the minimum.

Having tube pass designed for the water and the shell pass for the air, the shell and tube cooler is adopted to the centrifugal air compressor. In addition to the features of easy cleaning and low maintenance, the shell and tube cooler has the design of fin heat dissipation, which can ensure efficient heat dissipation and low pressure drop.

The structure of the gearbox is split horizontally to have slight positioning, which can ensure the repeated installation to be easy. The core components inside can be checked without dismounting the pipeline. Additionally, our radial air compressor has low maintenance cost.

Features of Centrifugal Air Compressor

1. High Quality Air Supply

The centrifugal air compressor obtains the required compressed air via the working process of air intake, acceleration, pressurization and exhaust. The entire air circuit system is isolated from the lubrication and the compressed air has no lubrication oil pollution. The 100% oil-less compression is achieved.

2. Safe and Reliable Operation

We adopt the high-end kinetic analysis to do strength calculation and fluid mechanical analysis on the impeller in the design phase of our radial compressor. It can ensure the impeller to have impact resistance, fatigue resistance and safe and reliable operation.

3. Easy Installation and Low Maintenance

With the design of high-performance system, our centrifugal air compressor has reasonably compact structure. Having horizontally split structure, the gearbox can have its cover dismounted for the maintenance of its gears and bearings. Moreover, our centrifugal air compressor is capable of having precision installation on the construction site.

4. Effective and Controllable Data

Having the touch screen of large LCD color screen, our centrifugal air compressor can clearly display the operating parameters. In addition to the high-precision microcomputer control, our centrifugal air compressor also has remote coordinated control system, which has excellent compatibility and can link the different control systems of customers to realize remote control.

5. High Energy Efficiency

We adopt the anti-surge technology and the advanced automatic duplex and voltage regulation control to our centrifugal air compressor. Via the air release valve and air intake valve, our centrifugal air compressor can have automatic control to maintain a stable exhaust pressure. Our centrifugal air compressor is always in an efficientrunning status and can adjust the air volume as required in various working conditions.

6. Low Maintenance Cost

Having reasonably designed integral structure, our centrifugal air compressor has low maintenance cost.

Structure and Core Components

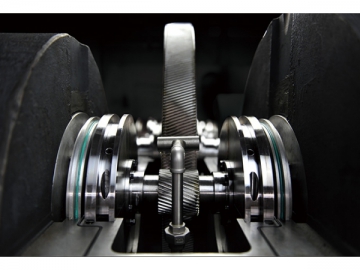

1. Overdrive Gear System: High Performance and Extended Lifespan

Our centrifugal air compressor has the spiral gear system featuring high precision, small mode number and large gear ratio. Passing the precision dynamic balancing test, the gear system has smooth rotation without vibration. After having the nitrogen treatment, the gear tooth surface has excellent wear resistance and longer lifespan.

2. Diffuser: Efficient Conversion and Rapid Increase in Pressure

Blowing from the high-speed rotary impeller, the airflow passes the diffuser and the airflow velocity decreases rapidly. Correspondingly, the air pressure is rapidly converted to the pressure energy.

3 Bearing: Oil Film Design and High Speed Running

Having the design of oil film, all the bearings of our centrifugal air compressor have no vibration and will not touch the high-speed rotary axle. Additionally, the bearings can work under lower temperature.

4. Air Seal and Oil Seal: 100% Oil-Free Air Compression

The high-strength aluminum alloy and non-contact labyrinth design have ensured the tightness of air seal and oil seal at all levels of the centrifugal air compressor. Consequently, the compressed air is 100% oil-free.

5. Air Intake Valve: Automatic Control and Reduced Energy Consumption

The air intake valve is controlled by a computer and can automatically control the volume of air intake according to your required volume of compressed air. The airflow can have pre-rotation conforming to the impeller’s direction of rotation, which ensures a stable, smooth and energy saving supply of compressed air.

6. Impeller: Back Bending Design and Energy Conservation

Having the back bending design, our centrifugal air compressor’s impeller has extremely high efficiency in the entire range of operation. Made of high-strength stainless steel, the impeller has good corrosion resistance and wear resistance.

Parameter of Centrifugal Air Compressor

Standard Condition

1. Medium: Air

2. Air Pressure: 1bar(A)

3. Air Intake Temperature: Below 35°C

4. Relative Humidity: Below 60%

5. Cooling Water Temperature: Below 32°C

The centrifugal air compressor has a wide range of performance options.

Flow Range: 40 m3/min -1,000 m3/min

Air Pressure: 2.1-10.5Bar. If required, the highest pressure can be up to 40Bar

The design and manufacturing are according to the API international standard.

Application

Mining, Chemical Industry, Power, Metallurgy

| Types | | | | |

| Air Intake Volume (m3/min) | 42-90 | 90-140 | 140-200 | 200-300 |

| Exhaust Pressure (kg/cm2) | 5-10 | 5-10 | 5-10 | 5-10 |

| Power (kw) | 185-400 | 400-700 | 700-1,050 | 1,050-1,500 |