Nitrogen/Hydrogen Generator by Ammonia Decomposition

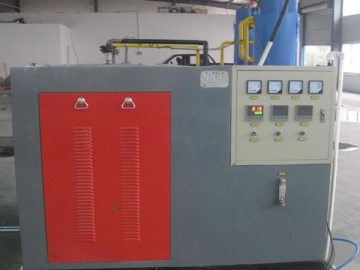

The nitrogen/hydrogen generator by ammonia decomposition is designed on the basis of invaluable industrial experience and meticulous sense of practice. This ammonia decomposition furnace excels at supplying high-quality protective gas or reduction gas for heat treatment in various industries.

Process

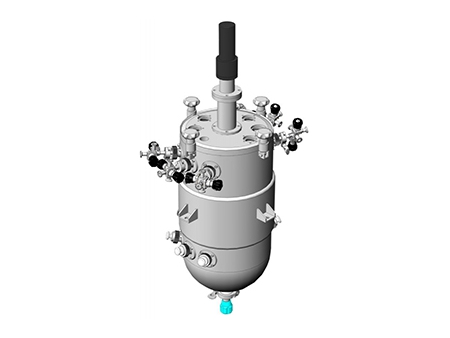

This nitrogen/hydrogen generator vaporizes and preheats liquid ammonia. Then the gas flows into decomposition furnace filled with catalysts. Under circumstance of certain temperature and catalysts, ammonia is decomposed into mixed gas containing 75% hydrogen and 25% nitrogen.

The mixed gas goes through heat exchanger and cooling system into the dryer filled with zeolite molecular sieves supplied by UOP. Purification process afterwards removes residual ammonia and water out of the mixed gas.

Application

1. Our air separation equipment generates protective gas for bright annealing of plates, belts, wires, pipes and standard parts applicable for industries of ferrous and non-ferrous metallurgy, as well as machinery.

2. This hydrogen generator by ammonia decomposition has been seen in sintering of powder metallurgy, tungsten-molybdenum material, hard alloy and electronic material, etc.

3. The nitrogen/hydrogen generator is well-suited for supplying protective gas to tin bath in production of float glass.

4. Our nitrogen generator by ammonia decomposition is also recommended for sintering of high temperature refractory material.

5. This chemical separation equipment finds application for offering reduction gas to chemical industry.

Advantage

1. Superior reliability

Hearth adopts 0Cr25Ni20 stainless steel seamless tube, showing outstanding resistance against high temperature and corrosion. Heating component is made up of nickel chromium alloy featuring prominent mechanical properties in high temperature. As a result, the entire nitrogen/hydrogen generator exhibits exceptional service life.

2. Energy efficiency

Ammonia decomposition requires no water utilization. Heat of decomposition is used to pre-heat ammonia which reduces electricity consumption.

3. Easy operation

Compact structure is the result from comprehensive technology and vigilance. Skid mount method requires minimized floor space and no infrastructure. Hydrogen production only needs power supply and air supply.

4. Wide application

Our nitrogen/hydrogen generator caters to most hydrogen application needs, especially in metal heat treatment, powder metallurgy and electronics, etc.

5. Cost effectiveness

Our equipment is highly recommended for those who want the most leading technology at the affordable price. Moreover, liquid ammonia is cheap. Therefore, our product is the blend of economy and technology.

| No. | Air flow | Power supply | Power | Overall dimension | Weight | Inlet | Outlet | Air exhaust | Sample port | Discharge outlet | Water inlet/outlet | Water consumption | Working temperature | Residual ammonia | Dew point | Oxygen content |

| Nm3/h | V, Hz | kW | mm×mm×mm | t | DN | DN | DN | Φ | G | G | t/h | ℃ | ppm | ℃ | ppm | |

| 1 | 5 | 220,50 | 6 | 1000×1150×1600 | 0.3 | 10 | 10 | 10 | 6 | 1/4 | 0 | 0 | Up to 800 | 1000 | -10 | 5 |

| 2 | 10 | 380,50 | 12 | 1200×1400×1600 | 0.8 | 15 | 15 | 15 | 6 | 1/4 | 0 | 0 | Up to 800 | 1000 | -10 | 5 |

| 3 | 20 | 380,50 | 22 | 1600×1800×1600 | 1 | 15 | 25 | 15 | 6 | 1/2 | 1/2 | 0.2 | Up to 800 | 1000 | -10 | 5 |

| 4 | 30 | 380,50 | 32 | 1600×1800×1600 | 1.2 | 15 | 25 | 15 | 6 | 1/2 | 1/2 | 0.2 | Up to 800 | 1000 | -10 | 5 |

| 5 | 40 | 380,50 | 36 | 1800×1800×2500 | 1.5 | 25 | 40 | 25 | 6 | 1/2 | 1/2 | 0.4 | Up to 800 | 1000 | -10 | 5 |

| 6 | 50 | 380,50 | 44 | 1800×1800×2500 | 1.6 | 25 | 40 | 25 | 6 | 1/2 | 1/2 | 0.4 | Up to 800 | 1000 | -10 | 5 |

| 7 | 60 | 380,50 | 52 | 1800×1800×2500 | 1.7 | 25 | 40 | 25 | 6 | 1/2 | 1/2 | 0.4 | Up to 800 | 1000 | -10 | 5 |

| 8 | 70 | 380,50 | 58 | 1800×1800×2500 | 1.8 | 25 | 40 | 25 | 6 | 1/2 | 1/2 | 0.4 | Up to 800 | 1000 | -10 | 5 |

| 9 | 80 | 380,50 | 64 | 1800×1800×2500 | 1.9 | 25 | 40 | 25 | 6 | 1/2 | 1/2 | 0.4 | Up to 800 | 1000 | -10 | 5 |

| 10 | 90 | 380,50 | 83 | 2000×2200×2500 | 2.3 | 40 | 50 | 40 | 6 | 1/2 | 1/2 | 0.6 | Up to 800 | 1000 | -10 | 5 |

| 11 | 100 | 380,50 | 83 | 2000×2200×2500 | 2.4 | 40 | 50 | 40 | 6 | 1/2 | 1/2 | 0.6 | Up to 800 | 1000 | -10 | 5 |

| 12 | 110 | 380,50 | 96 | 2000×2200×2500 | 2.5 | 40 | 50 | 40 | 6 | 1/2 | 1/2 | 0.6 | Up to 800 | 1000 | -10 | 5 |

| 13 | 120 | 380,50 | 96 | 2000×2200×2500 | 2.6 | 40 | 50 | 40 | 6 | 1/2 | 1/2 | 0.6 | Up to 800 | 1000 | -10 | 5 |

| 14 | 140 | 380,50 | 111 | 2100×2300×2700 | 2.7 | 40 | 50 | 40 | 6 | 1/2 | 3/4 | 0.8 | Up to 800 | 1000 | -10 | 5 |

| 15 | 150 | 380,50 | 128 | 2100×2300×2700 | 2.8 | 40 | 50 | 40 | 6 | 1/2 | 3/4 | 0.8 | Up to 800 | 1000 | -10 | 5 |

| 16 | 160 | 380,50 | 128 | 2100×2300×2700 | 2.9 | 40 | 50 | 40 | 6 | 1/2 | 3/4 | 0.8 | Up to 800 | 1000 | -10 | 5 |

| 17 | 180 | 380,50 | 143 | 2300×2600×2700 | 3.6 | 50 | 65 | 50 | 6 | 1/2 | 3/4 | 1 | Up to 800 | 1000 | -10 | 5 |

| 18 | 200 | 380,50 | 157 | 2300×2600×2700 | 3.8 | 50 | 65 | 50 | 6 | 1/2 | 3/4 | 1 | Up to 800 | 1000 | -10 | 5 |

- Amorphous Alloy Powder Equipment

- Suspension Melting Furnace

- Mesh Belt Atmosphere Brazing Furnace

Related Names

Ammonia Cracker | Hydrogen Making Machine | Gas Generator | Gas Generation System