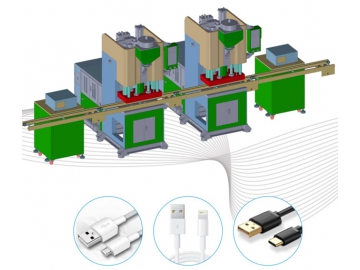

Two-Platen Injection Molding Machine

Designed to mold medium to large plastic parts efficiently, this two-platen injection molding machine integrates features that boost its performance and usability. The plastic injection molding machine uses low-friction linear guides for mold locking, speeding up both the mold opening and closing processes. A screw, specially designed with a high L/D ratio, enhances the plasticizing capabilities, allowing for consistent and effective molding. Linear guides support the lock mold and injection platform, reducing resistance and wear and providing smooth operation with precise mold locking accuracy of up to ±1%. This plastic injection machine handles clamping forces from 500 to 4000 tons, suitable for a wide range of molding tasks.

- Injection stroke: 420mm-1310mm

- Injection capacity: 1688g-45293g

- Injection pressure: 1259kgf/cm²-2466kgf/cm²

- Injection rate: 495g/s-2910g/s

- Clamping force: 500tonf-4000tonf

- Ejector stroke: 250mm-550mm

- Drive system: hydraulic/hybrid

The injection molding machine is perfect for manufacturing large plastic items such as automotive bumpers, dashboard components, and air conditioning compressor casings. It is also suitable for producing heavy-duty plastic pallets for loads exceeding 3000 tons, demonstrating its capability to handle diverse industrial molding needs.

Samples of Plastic Injection Molded Parts Car Fender

Car Fender Car Bumper

Car Bumper- Injection molding of storage box

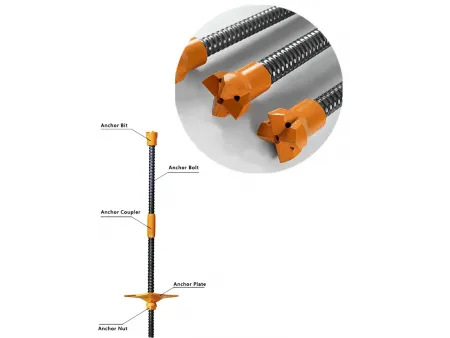

Engineered for precise engagement and strong locking force, ensuring stable and reliable molding.

Incorporates high-pressure cylinders and valves for even force distribution and robust lock mold force during injection processes.

The system includes a high-pressure release for mold opening, which boosts the opening force and ensures smooth operations, alongside low-pressure protection to extend mold life.

Features a multi-axis drive mechanism that provides stability and precision throughout the injection process.

This feature overcomes factory height limitations and simplifies mold installation, especially for large molds that cannot be loaded from the top of the machine.

Specifically designed for two-platen machines, this moving platen support structure ensures the parallelism and accuracy of the platen's movement, even when heavy molds are mounted.

The platens are designed with the aid of Finite Element Method (FEM) analysis to ensure uniform force distribution across the machine and mold. This extends machine lifespan and enhances product quality.

- The design includes durable structures from leading European manufacturers, enhancing the injection molding machine's longevity.

- Its compact lock mechanism reduces space requirements in factories by over 30%.

- Offers a large mold stroke and capacity, making it ideal for producing a wide variety of products, including large deep bucket-type items.

- Designed with minimal elbow-joint wear, the molding system requires less lubrication and reduces maintenance costs.

- a supplementary pressure cylinder maintains precise lock mold force within a ±1% error margin during injection.

| Model | UNIT | ||||||||||||||||

| Injection Unit | Type | - | 4600 | 5900 | 7000 | 8200 | 10300 | ||||||||||

| Screw diameter | mm | 75 | 85 | 95 | 85 | 95 | 105 | 95 | 100 | 110 | 100 | 110 | 120 | 110 | 120 | 130 | |

| Injection stroke | mm | 420 | 430 | 450 | 495 | 540 | |||||||||||

| Theoretical shot volume | cm³ | 1855 | 2382 | 2976 | 2439 | 3046 | 3721 | 3188 | 3533 | 4274 | 3886 | 4702 | 5595 | 5129 | 6104 | 7164 | |

| Shot weight of injection (PS) | gram | 1688 | 2168 | 2708 | 2219 | 2772 | 3387 | 2901 | 3215 | 3890 | 3536 | 4279 | 5092 | 4668 | 5555 | 6519 | |

| Injection pressure | kgf/cm² | 2466 | 1920 | 1537 | 2445 | 1957 | 1602 | 2199 | 1985 | 1640 | 2117 | 1749 | 1470 | 2008 | 1687 | 1438 | |

| Injection speed | mm/sec | 123 | 126 | 112 | 105 | 106 | |||||||||||

| Injection rate | cm³/sec | 495 | 636 | 794 | 649 | 811 | 991 | 722 | 800 | 968 | 750 | 907 | 1080 | 912 | 1085 | 1274 | |

| Mold Clamping Unit | Mold clamping force | tonf | 500 | 1100 | |||||||||||||

| Mold clamping stroke | mm | 1250/750 | 2050/1400 | ||||||||||||||

| Mold thickness | mm | 400~900 | 600~1250 | ||||||||||||||

| Max. weight of mold | tonf | 5 | 13 | ||||||||||||||

| Daylight | mm | 1650 | 2650 | ||||||||||||||

| Suggested min mold diameter (H×V) | mm | 640×570 | 875×785 | ||||||||||||||

| Tie bar spacing (H×V) | mm | 910×810 | 1250×1120 | ||||||||||||||

| Mold platen (H×V) | mm | 1380×1280 | 1800×1680 | ||||||||||||||

| Ejector stroke | mm | 250 | 350 | ||||||||||||||

| Ejector force | tonf | 11 | 23.9 | ||||||||||||||

| Electrical Equipment | Max. pump driving motor | kW | 45*2 | 45 30*2 | 45 30*2 | 45 30*2 | 45*3 | ||||||||||

| Temperature controller | (range)set | (0-400C)×8 | (0-400℃)×8 | ( 0-400℃)×8 | ( 0-400℃)×8 | ( 0-400C)×8 | |||||||||||

| Heater capacity | kW | 37.55 | 43.77 | 46.27 | 51.29 | 63.38 | |||||||||||

| General | Machine dimensions (L×W×H) | mm | 8200×2700×2200 | 11400×3400×2650 | |||||||||||||

| Oil tank capacity | liter | 1210 | 2250 | ||||||||||||||

| Machine weight | metric tons | 26 | 70 | ||||||||||||||

| Max. system pressure | kgf/cm² | 140 | 140 | 140 | 140 | 140 | |||||||||||