Industry Water Supply

Water Pump for Industry Water Supply

MARQUIS is a professional industrial water pump provider, and our pumps have been extensively utilized in industry water supply, covering metal, plastic, rubber, electronic product and mechanical equipment. With decades of experience in this field, we can provide different pumping solutions for various kinds of hot, flammable, corrosive or high-pressure liquids, and our water pumps will be your ideal choice under the condition that only a small installation space is available or higher energy efficiency is required.

If you are planning to build up a new production line or a new system, we recommend you to communicate with us as soon as possible, because our pumps can be adjusted easily to meet your requirements and optimize the entire system. Moreover, we have branch companies in 45 countries all over the world, which makes it very easy for you to obtain professional technical support and spare parts in time.

The following paragraphs give brief introduction to the possible applications of our water pumps.

1. Water Supply

In different industries, requirement on water supply varies greatly. Some ask for frequent water supply in small amount, while others need rapid water delivery with no influence on the water supply for other systems. So, our water pumps are elaborately designed to guarantee constant water pressure and flow rate during utilization. If necessary, the advanced water measurement and control system can be applied for water quality supervision and control.

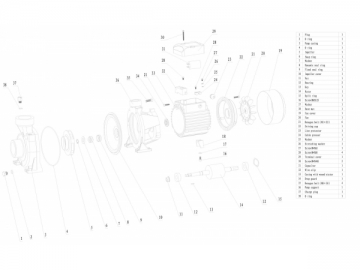

According to customers' requirement, customized water pumps can be manufactured to offer water supply with accurate pressure, including single-stage water pump, multi-stage water pump as well as booster pump. In addition, our water pumps are compliant with relevant standards for drinking water pump, while variable frequency motor and pump controller can be equipped to the booster pump.

2. Washing

Washing treatment, as a part of production line or an independent unit, is actually indispensable in most industries, if not all of them. Generally speaking, the washing equipment includes bottle washing machine, machine part cleaning machine, car washing system, movable cleaning system, clean-in-place system, and sterilization-in-place system.

Being the essential part for the cleaning system, our single-stage, multi-stage or submersible water pump have been fully optimized to withstand corrosive detergent, high temperature as well as frequent start and stop. These pumps can be either sanitary or non-sanitary type.

If equipped with a frequency converter, the compact water pump could provide three cleaning pressures for liquid soap spraying (low pressure), on-site cleaning (high pressure), and high-pressure washing (very high pressure), respectively. Moreover, a metering pump can be installed onto the water pump so as to help operators add additives in precise dosage.

3. Cooling and Refrigerating

Cooling system plays an exceptionally important role for cooling towers, machining centres and other industrial applications. Therefore, a highly reliable cooling solution is of great importance.

Our cooling pump is particularly suitable for brine, ethanediol, liquid ammonia, liquid carbon dioxide and even Freon. Though our product suits well for a wide range of liquids, we specially design its shaft seal according to every specific application, and this mainly refers to optimized safety, durability and efficiency. Meanwhile, to ensure accurate dosage of chemical additives, a metering pump shall be used as well. Aside from cooling pumps, tailored air conditioning solution is also available.

4. Clean-in-Place

The clean-in-place system is generally adopted by enterprises that pay great attention to sanitation and pollution, because it could clean storage tanks, pipelines and entire production lines without dismantling them, thus saving both time and money.

Our clean-in-place water pump is made of stainless steel, and it can withstanding high temperature (110°C) and corrosive detergent. For food and pharmaceutical industries, sanitary pump is not necessary since the clean-in-place system doesn't come into contact with the production process. However, electropolishing is still required to ensure that there is no residue inside the pump casing. With necessary detergent and precise metering pump, the cleaning process could be further speeded up.

For sterilization purpose, our multi-stage water pump can be applied to supply water to boilers, and the generated steam is able to clean bottles and other objects effectively under extremely high temperature.

5. Fire Protection

The working efficiency of pump is quite important in case of emergent fire fighting scenes, and our fire fighting pumps boast very high efficiency and reliability, making it suitable for both onshore and offshore fire protection.

The onshore fire protection solution relies on the entire pumping system, including pipeline booster pump and main pump (driven by diesel motor or electricity), while the dedicated offshore fire pump is commonly seen in ships and oil rigs. Our product is able to deal with all kinds of fire fighting media (water, foam, etc.), and its size fit for different applications.

MARQUIS fire fighting pump and pumping system are compliant with current laws and regulations for fire protection.