Material Industry

1. Heat treatment

We provide a fabulous assortment of heat treatment equipment applicable for normalizing, annealing, quench, atmosphere sintering and brazing of various materials.

Material thermal processing is one of the predominant processes in machinery manufacture. Compared to other techniques, heat treatment normally brings no changes to workpiece shape and chemical composition. Instead, it changes micro-structure inside workpiece or surface chemical composition to better overall properties.

Classification

Normalizing: eliminates internal stress and reduces hardness of material

Annealing: reduces hardness, increases ductility, eliminates residual stress, secures dimension, minimizes deformation and crack, refines grain, adjusts structure and eliminates defects

Quench: promotes hardness, toughness, abrasion resistance, fatigue strength and rigidity

Tempering: eliminates residual stress caused in quench to prevent deformation and crack, alters hardness, rigidity, ductility and toughness to desirable value, secures dimension for accuracy, improves processability.

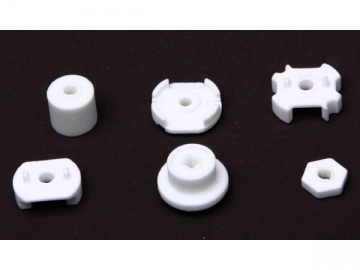

2. Powder materials

Powder material properties determine the properties of powder metallurgy products. Properties of powder materials comprise followings.

Geometric property: particle size, specific surface area, pore diameter and shape, etc.

Chemical property: chemical composition, purity, oxygen content and acid-insoluble substance, etc.

Mechanical property: apparent density, fluidity, formability, compressibility, angle of repose and shear angle, etc.

Physical and surface property: true density, glossiness, absorption, surfactivity and magnetic property, etc.

With the rapid development of powder metallurgy materials and products, more demanding quality needs lead to more versatile powder production equipment. We are highly renowned for offering a substantial number of machines covering water atomization powder manufacturing equipment, vacuum gas atomization powder manufacturing equipment, plasma atomization powder production equipment and amorphous powder equipment, etc.

These machines are capable of producing most powders on markets including all kinds of ceramic powders and various alloy powders such as iron-based, nickel-based, copper-based, silver-based and gold-based, etc.

- Vacuum Gas Atomization Powder Manufacturing Equipment

- Dual-chamber Vacuum Oil Quenching Furnace

- Amorphous Alloy Powder Equipment