Equipment

Quality equipment is an essential part of stamping die production processes. Most of Jiarun's production and testing equipment is purchased from well-known companies from around the world, making a great addition to our manufacturing capability.

The following is a list of current equipment in our workshops and testing labs.

We own and operate 15 stamping presses, with tonnage ratings from 25t to 220t.

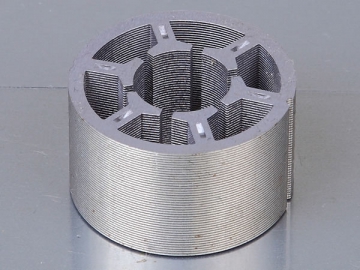

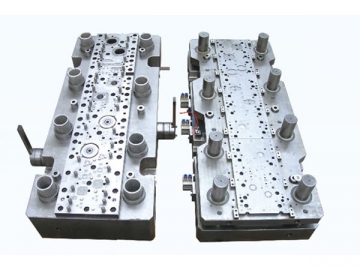

In our tooling workshop, experienced workers use large-scale grinding machines, CNC machining centers, stamping presses, and jig grinders (imported from the US) to produce high volumes of quality press tools and metal stamping parts.

Our in-house wire EDM capability includes making precise cuts and shapes from hardened steels, and ensuring all components are manufactured to the tightest tolerances, using 5 low-speed and 10 high-speed wire EDM machines.

The 15 grinding machines can add the final touches onto the assembled press dies.

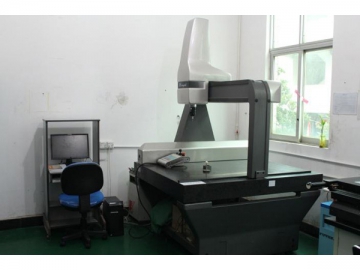

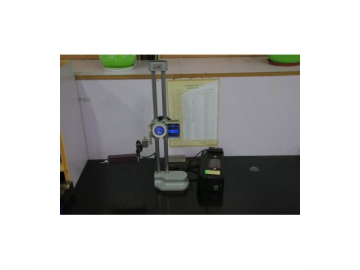

The testing lab is outfitted with an array of testing equipment, including a 3 coordinate measuring machine imported from Germany, a height meter, a hardness tester, projector, microscope, caliper, and the micrometer. This equipment ensures JR metal stamping die is precisely sized and will perform according to customer's specific stamping presses.