Multi-Purpose Continuous Fryer

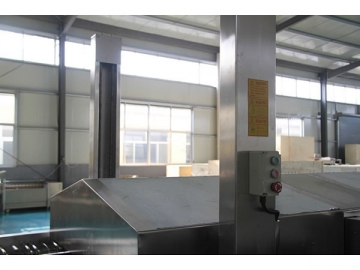

Continuous Fryer / Food Processing Deep Frying Machine / Food Deep Frying Machine

Typical Applications

Hash brown

Hash brown  Bulges

Bulges  Tortilla chips

Tortilla chips

Bananna chips

Bananna chips  Fried chicken

Fried chicken  Meat patties

Meat patties

French fry processing line

Product Details

Fryer belt

Fryer belt  Slag removal

Slag removal  Cover hoister

Cover hoister

Features

Precise temperature control in multiple heating zones

Rapid temperature adjustment according to product load changes

Circulation of oil through a continuous filter with a rapid fast fines removal

Patented auto extinguishing system

Easy to clean and access to maintenance with a modular design

We use a technology that heats from the middle oil layer in order to control the upper oil layer’s temperatures. This effectively reduces the oxidation degree, and restricts the acid value growth, thereby prolonging the usage time of the cooking oil. Through an acid value test on our new frying machine in a continuous 24 hour period, we determined the POV value was 1.40 and the acid value was 0.062/100g. This result is less than national standards for food hygiene of POV 4.00 and acid value of 0.015/100g, making the oil safe for human consumption. It prolongs the oil usage period, and reduces waste, saving 50% more oil than traditional frying machines.

Food leavings, unnecessary water, and heavy metals are removed from the high temperature area and sink into a low temperature area, then drained away with water. When the oil is excessively dry, the water layer can provide appropriate water for the oil layer, in order to prevent carbonization in the fried food. This reduces the risk of potentially harmful elements and protects consumer health. According to the inspection report from the Environmental Monitoring Station, the average value density of fumes vented by an ordinary frying pan is about 6.16mg/m3 while our deep frying machine is only about 1.96mg/m3. This is 1/3 less than an ordinary frying pan.

Taking advantage of all of these features, Xindaxin’s continuous frying machine delivers products with a uniform color and taste. A wide range of applications also allows the multi-purpose continuous fryer to be designed to suit your specific needs.

By using this system, we design and provide complete solutions for:

1. Potato chip production lines

2. French fry production lines

3. Nugget (chicken, vegetable mix, beef) production line

4. Hamburger production line

5. Seeds and nuts production line

We are a one-stop shop for equipment, warranties, services and spare parts. Simply contact us for details.

Specification

| Model | Electric Heating* | Dimensions |

| 24kw | Customized according to project | |

| 30kw | ||

| 36kw | ||

| 48kw | ||

| 75kw | ||

| 90kw | ||

| 120kw | ||

| 150kw | ||

| 168kw |

* Heating methods include electric, gas, fire coal or conduction oil