JSK-60 Series

The JSK-60 series control cabinet is designed to control liquid pumps that feature a power of no more than 22kW. By working together with a float switch, the JSK control paneller is capable of determining the liquid level and automatically turning the pump on and off.

Starting manner: under full voltage

Protection for: overload, open phase, leakage (motors with a power of 5.5kw and above), and overheat protection for pumps whose power is beyond 15kw

Model Number Meaning: SK 60 □/□

JSK: Jushen electromagnetic control cabinet

60: models that adopt overheat relay for protection; 61: models that adopt motor protector

□: pump power (Kw)

□: number of liquid pumps the cabinet can control

Null: 1 cabinet for 1 pump

2: 1 cabinet for 2 pumps

3: 1 cabinet for 3 pumps

Main Features

1. Control system: manual, automatic (hydraulic), PLC remote control

2. Indicators (bright LEDs) for power, working condition, error, overheating, leakage, and liquid level

3. Automatic conversion: once an error happens to the pump, the water level control device will cut off the incorrectly operating motor and automatically switch to the spare. The fault history of the first motor will be saved.

4. The main and spare pumps are alternatively used, each for 4 to 8 hours.

5. The main and spare pumps alternatively operate at regular intervals determined by the liquid levels.

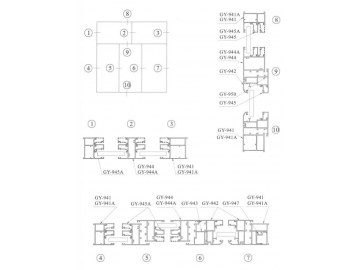

Automatic Liquid Level Control

1. A liquid level alarm is used in cabinets that control 2 or 3 pumps, creating a safer environment for DC 12V switch power.

2. How does the universal mercury float switch work?

a. 2 float balls (more for ultra-high liquid level): The upper float ball (high liquid level) turns on the pump, and the lower float ball (low liquid level) turns off the pump

b. 3 float balls (more for ultra-high liquid level): the second pump is turned on at high liquid levels, and turned off when the liquid drops to the medium level; the first pump turns on at medium level and turns off at low level

3. How does the KEY float ball work?

Each KEY ball can turn the pump on at high level (h1), and turn it off at low level (h2). With n balls working at 2n points to control the pumps, the system runs at a highly efficient level.

Working Environment

1. Ambient temperature: -5 ~ 40℃; no more than 35℃ on average in 24 hours

2. Altitude: ≤2000m

3. Relative humidity: no more than 50% at 40℃; when the ambient temperature is low, a high relative humidity is acceptable, for example, 90% humidity is allowed at 20℃; condensation can occur occasionally on the panel surface

4. Non-explosive: no corrosive gas or conductive dust to wear down the panel's electrical performance.

5. Installation: the tilt angle is no more than 5°

6. Power: rated voltage 380V±%, 50Hz

7. Working cycle: work continuously for 8 hours or longer

8. Rated operating frequency: 16 time/h; for motors of more than 7.5kw, it is 12 time/h

Technical Parameters

√ means available;

※ means optional (if an alternate mode is required, please specify if the alternating interval is determined by regular timing or liquid level)

| Model | Rated current (A) | Motor power (kW) | Functions | Dimension (mm) (W×H×T) | |||||||||

| error alarm | current display | remote display | remote control | liquid leakage | overheat | automatic conversion | alternate use | 1 panel, 1 pump | 1 panel, 2 pumps | 1 panel, 3 pumps | |||

| JSK60-4 | 8.5 | 0.75-4 | √ | √ | ※ | √ | ※ | 300 × 400 × 200 | 400 × 500 × 200 | 400 × 600 × 200 | |||

| JSK60-5.5 | 11.5 | 5.5 | √ | √ | ※ | √ | √ | ※ | 300 × 400 × 200 | 400 × 500 × 200 | 500 × 700 × 200 | ||

| JSK60-7.5 | 15.5 | 7.5 | √ | √ | ※ | √ | √ | ※ | 300 × 400 × 200 | 400 × 500 × 200 | 500 × 700 × 200 | ||

| JSK60-9 | 18.0 | 9 | √ | √ | ※ | √ | √ | ※ | 300 × 400 × 200 | 400 × 500 × 200 | 500 × 700 × 200 | ||

| JSK60-11 | 22 | 11 | √ | ※ | √ | ※ | √ | ※ | √ | ※ | 300 × 400 × 200 | 400 × 500 × 200 | 500 × 700 × 200 |

| JSK60-15 | 30 | 15 | √ | ※ | √ | ※ | √ | ※ | √ | ※ | 400 × 500 × 200 | 400 × 600 × 200 | 500 × 700 × 200 |

| JSK60-18.5 | 37 | 18.5 | √ | √ | √ | ※ | √ | √ | √ | ※ | 400 × 500 × 200 | 400 × 600 × 200 | 600 × 800 × 300 |

| JSK60-22 | 44 | 22 | √ | √ | √ | ※ | √ | √ | √ | ※ | 400 × 500 × 200 | 400 × 600 × 200 | 600 × 800 × 300 |

You may also find products like:

Liquid Pump Controller, Water Level Control Device for Pump, Electric Control Panel, Electrical Panel Box