ERW API Tube Mill, 127mm-508mm

1 ERW76 Sizing section

ERW219 Forming section

ERW254 Sizing section

FF forming technology

Automatic stacking machine

This ERW API tube mill is designed for the production of API line pipes, petroleum casing pipes, and structural pipes with a diameter range of 273mm-508mm. The welding speed is 15~30m/min and the maximum output can reach 250,000T per year.

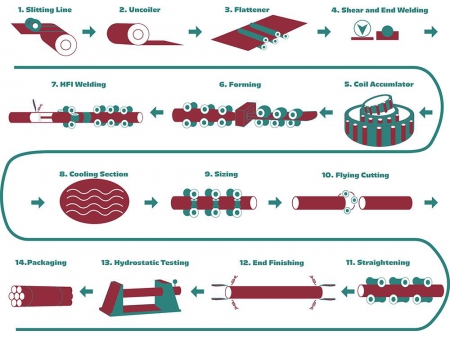

Production ProceduresCoil Loading → Uncoiling → Flattening/Leveling → Shearing & End Welding → Coil Accumulator → Forming → Welding → Inner & Outer Deburring → Annealing → Air & Water Cooling → Sizing & Straightening → Flying Saw Cutting → End Facing & Chamfering → Hydrostatic Testing → Ultrasonic Flaw Detection → Weighing & Measuring → Painting & Marking → Packaging → Warehouse Storage

Basic Technical Parameters- Raw Material Specifications

Steel grade:

Coil Outer Diameter: Ø1350mm~Ø2000mm

Line pipe: A, B, X42, X46, X52, X56, X60, X65, X70, X80

Petroleum casing pipe: H40, J55, K55, N80

Structural pipe: Q215, Q235, Q345, 20#

Coil Inner Diameter: Ø610~Ø762mm

Coil Weight: Max. 35T

Strip Width: 680mm~1600mm

Strip Thickness: 6mm~16mm

- Finished Pipe Specifications

Technical Standards: API 5L API 5CT GB/T 3091 JIS G3452 JIS G3444 JIS G3445 ASTM A513 EN 10219

Pipe Outer Diameter: Ø 219mm~Ø508mm

Pipe Length: 6~20m

Welding Speed: 15~30m/min

- Annual Output: 250,000 tons/year

- 4. Total Installed Capacity: Approx. 3,500 kW

- Improves serviceability and productivity

- Increase stability of the product quality

- Maximize output

- Lower equipment cost

- To satisfy small-batch production requirements of multiple products

- To improve the environment and safety during operation