Application

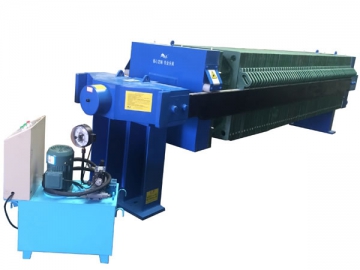

The hydraulic chamber filter press is most often used in a variety of industries, including chemical, metallurgy, pharmaceutical, lights, coal mining, food, environmental protection and energy supply, among others. The hydraulic filter press is available in either a medium or large volume size, and is our most popular choice, known for its ease of operation. The filter press opens and closes using a hydraulic cylinder, though an optional pressure holding model is available in either an automatic (electric) type, or a mechanical (lockout) type. Available plate sizes for the chamber are: 500mm, 630mm, 800mm, 920mm, 1000mm, 1250mm, 1500mm, 1600mm, and 2000mm.

Presentation

Electric powered hydraulic pumping units maintain hydraulic pressure within the chamber filter press. If the pressure exceeds the relief setting, the pressure is vented to lower the levels back to within the specified range. Though optional, electric hydraulics are known for decreasing filter opening and closing times, speeding up operations. For added operator and equipment protection, the hydraulic power unit is enclosed within the filter press leg that supports the hydraulic cylinder. The hydraulic cylinder includes a high volume, low pressure pump to open and close the plate stack quickly, and a low volume, high pressure pump to clamp the plate stack. Once the plate stack is closed, the high pressure hydraulic pump clamps the plate stack with enough force and safety features to counteract the pressure of the slurry feed. Electric hydraulics are used to monitor system status, and can be equipped with optional emergency stop devices and touch screen control of the filter press hydraulics.

Caution

The hydraulic chamber filter press is not very well suited for low solid content suspensions with small particles. Using it as such will result in a poor filtering performance, with particles slipping through the filter cloth, preventing the filtrate from being clean and clear.

Technical Parameters:

500 x 500mm | Filter Area M2 | Plate Quantity PCS | Chamber Quantity PCS | Filter Cake mm | Chamber Volume L |

| 4 | 9 | 10 | 25 | 50 |

| 6 | 14 | 15 | 75 |

| 8 | 19 | 20 | 100 |

| 10 | 24 | 25 | 125 |

| 12 | 29 | 30 | 150 |

| 14 | 34 | 35 | 175

|

630x630mm | Filter Area M2 | Plate Quantity PCS | Chamber Quantity PCS | Filter Cake mm | Chamber Volume L |

| 8 | 12 | 13 | 25 | 100 |

| 10 | 15 | 16 | 125 |

| 12 | 18 | 19 | 150 |

| 14 | 22 | 23 | 175 |

| 16 | 25 | 26 | 200 |

| 18 | 28 | 29 | 225 |

| 20 | 31 | 32 | 250 |

| 25 | 39 | 40 | 313 |

| 28 | 44 | 45 | 350 |

| 32 | 51 | 52 | 400

|

800x800mm | Filter Area M2 | Plate Quantity PCS | Chamber Quantity PCS | Filter Cake mm | Chamber Volume L |

| 20 | 19 | 20 | 32 | 320 |

| 30 | 29 | 30 | 480 |

| 40 | 39 | 40 | 640 |

| 50 | 49 | 50 | 800 |

| 60 | 59 | 60 | 960 |

| 70 | 69 | 70 | 1120 |

| 80 | 79 | 80 | 1280

|

920x920mm | Filter Area M2 | Plate Quantity PCS | Chamber Quantity PCS | Filter Cake mm | Chamber Volume L |

| 40 | 31 | 32 | 32 | 640 |

| 50 | 39 | 40 | 800 |

| 60 | 47 | 48 | 960 |

| 70 | 55 | 56 | 1120 |

| 80 | 63 | 64 | 1280 |

| 90 | 71 | 72 | 1440 |

| 100 | 79 | 80 | 1600

|

1000x1000mm | Filter Area M2 | Plate Quantity PCS | Chamber Quantity PCS | Filter Cake mm | Chamber Volume L |

| 32 | 19 | 20 | 30 | 480 |

| 40 | 23 | 24 | 600 |

| 50 | 29 | 30 | 750 |

| 60 | 35 | 36 | 900 |

| 70 | 41 | 42 | 1050 |

| 80 | 47 | 48 | 1200 |

| 90 | 53 | 54 | 1350 |

| 100 | 59 | 60 | 1500 |

| 120 | 71 | 72 | 1800

|

1250x1250mm | Filter Area M2 | Membrane Plate Quantity PCS | Recessed Plate Quantity PCS | Chamber Quantity PCS | Filter Cake mm | Chamber Volume L |

| 80 | 15 | 14 | 30 | 35 | 1400 |

| 100 | 19 | 18 | 38 | 1750 |

| 110 | 21 | 20 | 42 | 1925 |

| 120 | 23 | 22 | 46 | 2100 |

| 130 | 25 | 24 | 50 | 2275 |

| 140 | 27 | 26 | 54 | 2450 |

| 150 | 29 | 28 | 58 | 2625 |

| 160 | 31 | 30 | 62 | 2800 |

| 180 | 34 | 33 | 68 | 3150 |

| 200 | 38 | 37 | 76 | 3500 |

| 220 | 42 | 41 | 84 | 3850 |

| 250 | 48 | 47 | 96 | 4375 |

1500x1500mm | Filter Area M2 | Membrane Plate Quantity PCS | Recessed Plate Quantity PCS | Chamber Quantity PCS | Filter Cake mm | Chamber Volume L |

| 200 | 26 | 25 | 52 | 35 | 3500 |

| 224 | 28 | 27 | 58 | 3850 |

| 250 | 32 | 31 | 64 | 4735 |

| 280 | 36 | 35 | 72 | 4900 |

| 315 | 40 | 41 | 82 | 5250 |

| 340 | 45 | 44 | 88 | 6125 |

| 400 | 52 | 51 | 104 | 7000 |

| 450 | 58 | 57 | 116 | 7875 |

| 500 | 65 | 64 | 130 | 8750

|

1600 x 1600mm | Filter Area M2 | Plate Quantity PCS | Chamber Quantity PCS | Filter Cake mm | Chamber Volume L |

| 200 | 47 | 48 | 30 | 3025 |

| 224 | 52 | 53 | 3340 |

| 250 | 59 | 60 | 3780 |

| 280 | 66 | 67 | 4220 |

| 315 | 74 | 75 | 4725 |

| 340 | 80 | 81 | 5100 |

| 400 | 94 | 95 | 5985 |

| 450 | 106 | 107 | 6740 |

| 500 | 118 | 119 | 7500 |

| 560 | 132 | 133 | 8380

|

2000x2000mm | Filter Area M2 | Plate Quantity PCS | Chamber Quantity PCS | Filter Cake mm | Chamber Volume ㎥ |

| 560 | 79 | 80 | 35 | 9.8 |

| 630 | 89 | 90 | 11.03 |

| 700 | 99 | 100 | 12.25 |

| 770 | 109 | 110 | 13.48 |

| 840 | 119 | 120 | 14.7 |

| 910 | 129 | 130 | 15.93 |

| 980 | 139 | 140 | 17.15 |

| 1050 | 149 | 150 | 18.38 |

| 1120 | 159 | 160 | 19.6 |

| 1190 | 169 | 170 | 20.83

|